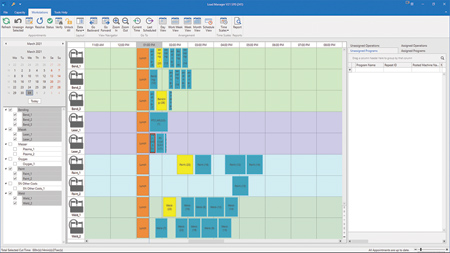

Load Manager and SigmaSCHEDULE offer flexible scheduling for nesting projects with operational dependencies.

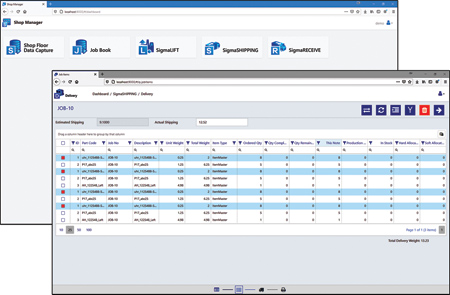

Handle shipping, receiving and logistics from the Shop Floor through browser-based Shop Manager applications.

SigmaNEST introduces clear nesting strategies based upon job priorities.

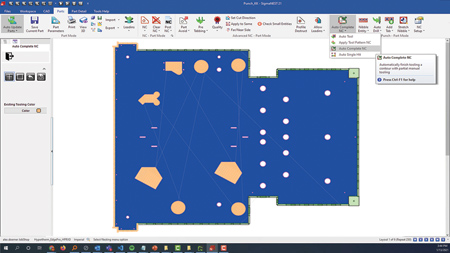

Auto Complete Tooling and View Punch Tasks Only make punch programming easier.

Parasolid and Rhino file import are now supported using CAD Import Plus.

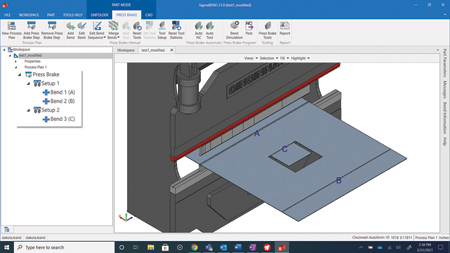

Multi-rail press brake operations are now supported by SigmaBEND.

CAMBRIO offers Version 21 of the SigmaNEST suite for fabricators. "SigmaSUITE continues to close the loop on manufacturing connectivity targeting 'The Connected Shop'-scheduling, quoting and logistics informed by nesting intelligence," said a company spokesperson. "This focus, along with CAD/CAM enhancements centered on simplicity and best manufacturing strategies, continues to strengthen SigmaNEST capabilities."

The Connected Shop

The aim of the Connected Shop is to bridge CRM, ordering, inventory, production, delivery and accounting. New software products and enhancements to the Business Systems and Shop Floor products have expanded this integration.

"The debut of SigmaSCHEDULE brings true dynamic scheduling unique in the fabrication industry," said the spokesperson. Users can plan projects with nested programs, primary cutting operations and secondary operations such as bending. The software can be configured for specific business needs, but also has the flexibility to instantly adjust the workflow plan to inevitable changes. Users can schedule forward for the quickest timeline (as soon as possible), or backward from a fixed due date (just in time). Estimators can use preschedule jobs to ensure delivery dates can be met before accepting the order.

Load Manager software now has real-time load balancing to divide the work efficiently for machines and secondary operations while identifying any sequence dependencies within the timeline. The software can also be used to automatically resolve the current day's schedule to compensate for disruptions, such as machine down time or "hot" jobs, to ensure job priorities are met.

Closing the Loop

Also new to the SigmaSUITE portfolio are SigmaSHIPPING and SigmaRECEIVE. These two browser-based apps simplify logistics on the shop floor with any smartphone or tablet, providing the ability to create delivery and dispatch notes and receive deliveries. Both apps give on-the-spot access to relevant delivery data, without the need of full MRP, and relay the status and location of the job without displaying confidential financial details.

SigmaQUOTE has more flexible features to aid good business practices. Tiered markups that reward priority clients, nuanced markups for specific materials or operations, and limited time promotions have been standardized and are easy to apply.

SigmaMRP offers better visibility and control with enhanced shop floor feedback throughout the workflow. Likewise, SimTrans boosts clarity through a user command center with dockable viewports and printable operational reports. The increasing integration between the Business Systems and Shop Floor products creates a closed loop of control in which each operation informs the next.

Clearer and Easy CAD/CAM

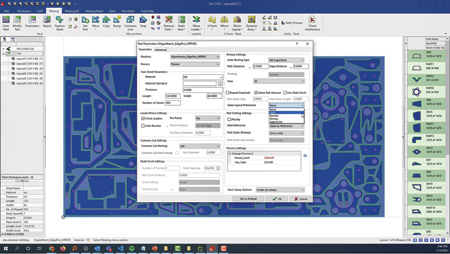

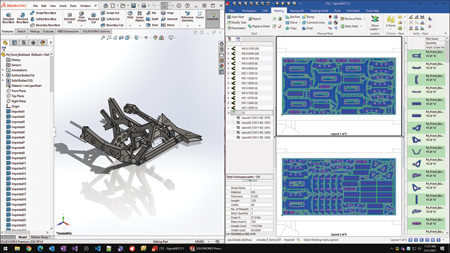

The flagship SigmaNEST product has been improved with intuitive nesting strategies and simplified controls for sheet layout preference and other task parameters. A new process selection feature for combi machines is particularly useful for defining specific technology settings such as toolpath lead-ins or NC parameters based on the cutting process.

Other major developments include enhanced common cut controls for edge quality and the ability to group patterns for fly cutting. With the development of the 3D environment, 3D beveling is improved with simpler tabbing and countersink holes, rule-based transitions and leads, and automatic ramping of the feedrate based on contour or hole size.

User experience for SigmaNEST Punch is improved with a clearer display of parts, shear hits, transformations and the ability to view only punch pattern actions on a program. A new automation Auto Complete Tooling allows the user to specify some punch details and allow the software to complete the task.

Significant developments within the 3D software products includes TrueShape Nesting for SigmaCTL for angle cuts and added nesting strategies for BestStickMixed or BestStickFixed. SigmaTUBE packages for SolidWorks and standalone feature enhancements to importing, marking and geometry support. SigmaUNFOLD, SigmaDEVELOP and SigmaBEND have advanced functionality for handling sharp bends, tooling and set-up reports and batch feedback tools.

CAD Import Plus now adds support for Parasolid and Rhino files to its growing collection of popular industry CAD formats. PDF and image import have been improved with enhanced OCR results, better identification of rotated text and the ability to import multipage PDF files. SimTrans' compatibility with CAD Import Plus provides fast conversion of 3D CAD files into SigmaNEST parts.

For more information contact:

CAMBRIO

1445 Kemper Meadow Drive

Cincinnati, OH 45240-1637

513-674-0005

www.cambrio.com