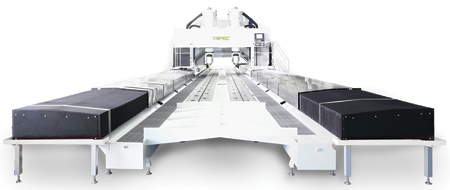

MC3200 Dual Head

SM_M AERO Series

APEC-Asian Pacific Elite Corporation and CNC Systems, Inc. have announced two new additions to the U.S. market.

MC3200 Dual

The first machine is the MC3200 Dual, Taiwan's first design of a single-beam with double 2-axis heads (5-axis simultaneously), double spindle and double tool magazine configuration that can be independently or synchronously activated while processing. "This results in a production capacity that is 200% higher than a single spindle design," said a spokesperson.

The table design is a one-body rigid casting that can lessen, reduce or remove vibration during machining and is engineered in lengths up to 20 m in X-axis.

APEC engineering designed the Y-axis as a one-body casting cross beam with an extra-large span between two guide ways. This helps ensure that static geometry error caused by the weight of ram and saddle will be balanced, resulting in dynamic/static rigidity and machining accuracy.

The X/U-axis processing stroke goes up to 20 m. With dual 2-axis heads and dual working areas, it can simultaneously process long and narrow wing structures such as wing stringer and wing beams on both sides of a large passenger aircraft. The maximum feedrate of the 3-axis is 40 m/min.

For chip and coolant control as well as safety, a full enclosure cover (with roof) is designed around the working area with a PVC curtain to isolate the outside pollution of oil mist and flying debris.

For automation, a gantry loader with a sub-table can be added to load and unload the parts. The finished parts can be clamped outside of the machine working area and replaced with raw materials to be loaded into the machine. This improves uptime and increases processing efficiency.

SM_M AERO Series

The SM_M AERO Series is an improved machine design from the APEC GM Series. With a symmetrical geometry design the box-in-box structure features full force flow and thermal symmetry and driving at the center of gravity (DCG). According to the company, some benefits of DCG include excellent dynamics, improved surface finish and reduced manual polishing time.

The heavy-duty ram is designed with honeycomb structure that applies the best balancing design and geometry. This design is also engineered for an automatic attachment head exchange system: head one can be HSK63A with 30,000 RPM or 24,000 RPM, while head two can be HSK100A with 20,000 RPM or 15,000 RPM-each with full 5-axis machining capabilities and their own automatic tool changers.

Machine configuration for aerospace machining:

- Cross beam flushing system

- Complex chip removal system

- Automatic top-roof cover

- High pressure pump with groups of powerful nozzles can quickly remove the chips

- Dual chip removal system with a large-capacity water tank can make coolant and chip removal stable and efficient

- Movable beam design of top-roof cover can prevent spreading of chips and coolant liquid.

Any APEC machine design can be set up for machining hard metals, aluminum or composites where a complete vacuum system and vacuum tables can be designed for a customer's specific requirements.

For more information contact:

Steven T. Arcari, President

Office: 207-985-6503

Cell: 860-575-5269

sarcari@cncsystem.com

Brian Arcari, Vice President

Office: 714-838-3999 x 777

Cell: 508-944-5099

brian@cncsystems.com

David M. Valentine, National Sales Manager

Office: 817-715-4746

Cell:949-599-5833

valentine@cncsystems.com

Parts: parts@cncsystems.com

Service: service@cncsystems.com

Website: www.cncsystems.com