The first of many Kingston HL model engine lathes sold-although this one was a somewhat rare 18" swing version only offered for a few years.

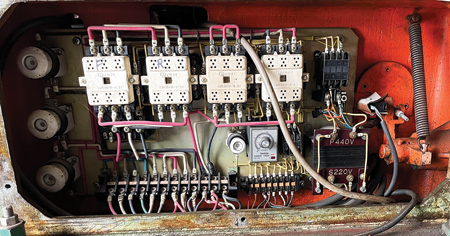

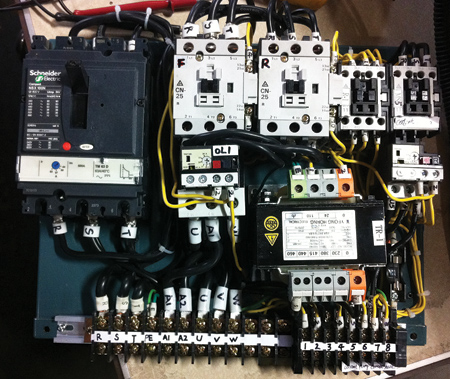

The old and new electrical panels for the Kingston HL lathe.

Kingston Parts Manager Gael Herve is no stranger to inquiries regarding old machines. In any given week he might quote dozens of parts for Kingston lathes older than Dynasty. It can be difficult to track the movement of these machines through secondary markets, over distance and over time, and sometimes there are surprises. Recently, he received a call from a service technician in Texas asking about parts for an early Kingston with an unusual pedigree. "After running the serial number I noticed it was the very first machine Kingston ever sold," said Herve. "I thought it was very cool."

Herve explained that the machine was the first of many HL model engine lathes sold-although this one was a somewhat rare 18" swing version only offered for a few years. The 3.15" bore HL-2000 (18" x 80") was shipped to San Antonio in May of 1977, before decades later making its 200-mile journey east on I-10 to its current home at one of the of the largest midstream oil and gas companies in North America. It is impossible to know exactly what went down in the 80s, 90s, 2000s and 2010s, but to Herve the mysterious address history is secondary.

"You have a machine that is more than 40 years old and still running smoothly," Herve said. "That is great. It means you are selling great quality and that is what customers are looking for."

Jose Gonzalez of B&K Mill Repair in Houston, TX, was charged with making the upgrades to this ancient warrior. Gonzalez, who has worked with "plenty of Kingstons" over the years, reached out to Kingston for all-new electrical components, a cross slide screw shaft and some brass nuts on the cross feed.

"Impressively, it is still in good condition," Gonzalez said. "But I am working with one of those companies where safety is priority number one. They have this machine in there to do repairs on their shop so they wanted some brand-new components on it. I am going to make sure they do not have any issues."

Sourcing parts for decades-old machinery can often be a real challenge. Herve has learned to be resourceful when attempting to find solutions for owners of old Kingston machines. In this case, the original electrical components were so old that the customer could not locate replacement parts to service the machine themselves. Kingston's Senior Engineer, Yanming Li, built a custom electrical panel for the HL-2000 based on the customer's needs-and sent the panel off to Gonzalez for a successful installation.

Kingston sold its last HL model in 2011-also into the Houston area-but there are "hundreds and hundreds" of older HLs out in circulation. "There is some strong HL love out there," noted Kingston President, Karen Lin. "Our factory in Taiwan continues to build significant numbers for Japan. In modern times this machine is fairly expensive to produce so it is hard to compete in North America, but it is still available by special order."

Another representative, who spoke on condition of anonymity, remarked on the paradox of producing machinery that can last 45 years: "It is a terrible business model," he joked. "This machine shipped a week after Star Wars came out. The real Star Wars."

Authored by Eric D. Anderson, Kingston Machine Tool

For more information contact:

Kingston Machine Tool Mfg, Inc.

5421 Business Drive

Huntington Beach, CA 92649

714-894-1648

sales@kingstonmachine.com

www.kingstonmachine.com