The CHIRON Group 715 Series enables short lead times and high level of autonomy due to integrated part handling automation.

The CHIRON Group 715 Series is fitted with a direct driven milling head that cooperates with the twin horizontal spindles for 6-sided machining of complex parts.

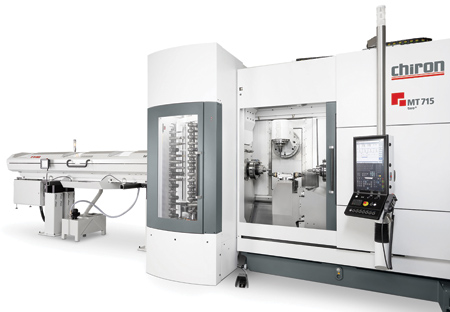

CHIRON Group has introduced the new 715 Series machining center. Designed for complete machining of all six sides of complex parts, the machine fits between the vertical CHIRON FZ 08 S mill turn precision+ machining center and the STAMA MT 733 machining center. It includes part handling automation and storage.

Matthias Efinger, Chiron Systems Engineer R&D, said, "the goal during development was to create a machining center designed for autonomous processing on all six sides, rounding off the CHIRON Group bar machining portfolio and fully bridging the gap between the FZ 08 S mill turn precision+ and MT 733."

The 715 Series is designed for fully automated, complete machining tasks in the medical technology, aviation and aerospace, energy and automotive industries. Part size range is bars up to o65 mm or chuck parts up to o200 mm, with maximum workpiece weight of 20 kg.

Continuous Machining Process

Two versions of the machining center are available: CHIRON MT 715 and CHIRON MP 715 (MT is Mill Turn and MP is Multi Profile). The machines include a direct-drive 20,000 RPM milling head, a horizontal main spindle and a matched, opposing counter spindle to permit continuous multifunctional machining on all six sides of a part in a single set-up. This capability is used to machine hip stems, turbine blades and extrusions for chassis or battery storage.

Both machines accommodate 128 tools and include integrated workpiece handling and workpiece storage. This supports fully automated, cost-reducing manufacturing of workpieces in small and medium batch sizes. Convenient loading and unloading of the tool magazine can occur during machining.

High Levels of Automation

The new machine platform is also set up to integrate digital systems from the CHIRON SmartLine Portfolio, including automatic condition monitoring, integrated machine and process diagnostics, machining simulation, preventive machine protection in every mode of operation, remote diagnostics and remote maintenance and intuitive operation.

Within the CHIRON Group portfolio is a range of options for machining workpieces with up to a 200 mm diameter and a length of up to 500 mm for milling and turning off the bar, or milling off the bar or from profile.

For more information contact:

CHIRON America, Inc.

10950 Withers Cove Park Drive

Charlotte, NC 28278

704-587-9526

info@chironamerica.com

www.chironamerica.us