Students supported by the igus young engineers support program developed a 3D printer with drylin linear units that offers cost-effective production of structural elements in space.

A student team supported by igus has developed a 3D printer with drylin linear units that offers cost-effective production of structural elements in space.

When booms for solar panels or satellite antennas are transported into space in a launch vehicle, they are exposed to high loads. The AIMIS-FYT team is working on a 3D printing process to simplify the complex transport and speed up production of the elements. The future goal is to manufacture parts directly in space.

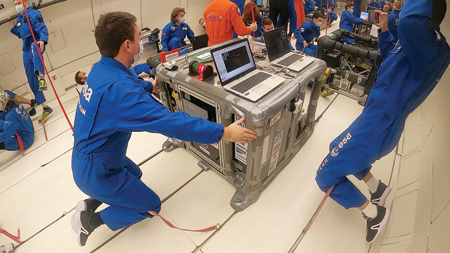

The students in AIMIS-FYT, as part of the young engineers support (yes) program by igus, built a 3D printer for experimental tests in weightlessness. For the drive technology, the students relied on maintenance-free and light drylin SAW linear axes.

Finding Alternative Solutions

"The process for getting devices into space is inefficient and expensive," said a company spokesperson. "The structural parts are designed primarily to withstand the high wind loads during the launch phase of a spacecraft. However, these structures are oversized for later operating times. Due to the high cost and limited space on a launcher, alternative solutions are required."

The AIMIS-FYT student team from Munich is working on a 3D printing process for cost-effective production in space as part of an aerospace engineering course.

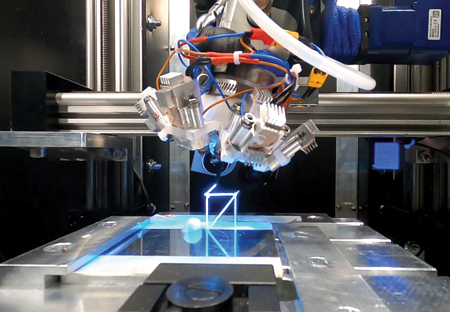

To solve this issue, students rely on photoreactive resin and UV light, which hardens the resin. A 3D printer had to be designed and built for experimental tests of the process in weightlessness.

In search of the right drive technology, the young engineers turned to igus and found the solution in the drylin SAW linear axes.

The linear modules are used in the two Z-axes and in the X-axis, thus forming the central drive unit. The linear axes are made with low weight aluminum and maintenance-free sliding elements made of high-performance plastics. The budding engineers used adjustable bearings to reduce the play of the lubricant-free and dirt-resistant polymer linear slider. A compact robolink D rotary axis with worm gear was built into the printer so that the printing filament can also be rotated.

Testing the Printer

To test the printer and the process, the team applied for and was accepted into the FlyYourThesis! Program of the European Space Agency (ESA). The parabolic flights took place in November and December 2020. If the aircraft reaches the apex of the climb and tips over into descent, microgravity occurs, which is very similar to weightlessness in space. The experiments were ideal conditions for a real test printer.

"The linear axes always ran without problems in all experiments, so we were able to print a small rod and also small truss structures for each parabola," said Torbon Schafer, a student on the AIMIS-FYT team.

Supporting Young Engineers

igus supports projects such as the AMIS-FYT experiment as part of its young engineers support program. With the university initiative, igus provides students and lecturers with free samples, university discounts and sponsorships and development of innovative products. Learn more about the program at www.igus.com/yes.

For more information contact:

igus, Inc.

P.O. Box 14349

East Providence, RI 02914

800-521-2747

sales@igus.com

www.igus.com