Flexible automation solution with DMG MORI AGV

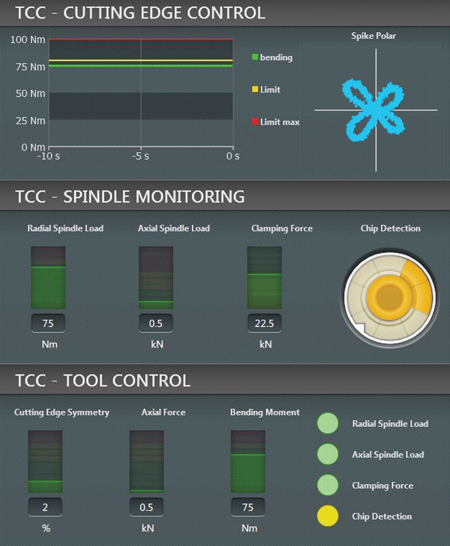

DMG MORI Tool Control Center TCC provides all relevant data on the CELOS side screen of the control

DMG MORI operates Technology Excellence Centers worldwide, including for the aerospace industry, which, in addition to developing industry-specific machine and technology solutions, also identify trends in the respective industries. Today, DMG MORI is focusing more than ever on the technology trends of automation and digitization. DMG MORI notes that the opportunities for increasing competitiveness in machining have never been greater than they are today, given the opportunities offered by these trends.

Automation today does not mean inflexible systems that need to be decided at the beginning of an investment project and then no longer can be changed. DMG MORI in-house developed and manufactured solutions are tailored to the respective machine tool and customer requirements. This can start with a prepared automation interface on the new machine tool for later retrofitting as soon as series production requires it. Depending on component sizes, workpiece handling systems such as the WH-Flex, pallet handling per machine such as round pallet storages RPS or a linear pallet pools LPP for the linking of several milling or mill-turn machines offer high productivity.

Automation is particularly flexible with the DMG MORI AGV. This automated guided vehicle orients and moves independently without induction loops in the hall floor and due to its sensor technology, collaborates safely with the employees on the same workspace without fencing. With the PH-AGV, pallets from storage areas can be brought to set-up stations and then directly into the machine tool. The layout of the machines and the storage areas is flexible. It can be integrated into existing layouts and later extended or changed at will. With the AGV technology, the TH-AGV in combination with a central tool storage (CTS) can be used to load tools into the machine or an AGV can even remove chips bins from the machine areas.

With automation, the need to automate processes in the machine tool is also increasing. Digitization helps to take decisive steps towards more intelligent machining. DMG MORI offers technology cycles comparable to assistance systems in modern cars. The sensor-based technology cycle Machine Protection Control (MPC) in a milling center monitors vibration, torque and shocks on the spindle and can thus avert damage from the machine in the event of a collision, comparable to a braking assistant in a vehicle. Imbalances or too great forces are detected and an automatic tool change can be initiated. In the highly sensitive spike sensor system of the tool control center (TCC), 20 sensors are installed in the spindle nose and follow the process in detail close to the cutting edge. For example, the bending moment of the tool is measured during cutting, which is an indicator of increasing tool wear during the process. In case of overrun or abnormalities, the machine can be stopped and, if possible, continue with a sister tool without the need of operator intervention.

Digitization in the machining process also means making data visible in a form, so that machine operators up to process engineers can work sensibly with this information. The DMG MORI Condition Analyzer offers this option. Process-relevant data are selected directly on the CELOS screen on the machine or a networked workstation and viewed via a timeline directly related to the NC program. This visualization provides the basis for using machine and process data to use analytics for data-based process optimization and process assurance and to move step-by-step closer to the vision of autonomous machining.

DMG MORI develops these solutions in close contact with selected customers and scientific institutes to make the topic of digitization in machining with on-board products tangible and usable for every customer.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

us.dmgmori.com