The EcoPaintJet applicator increases painting efficiency and offers companies more options when it comes to product design.

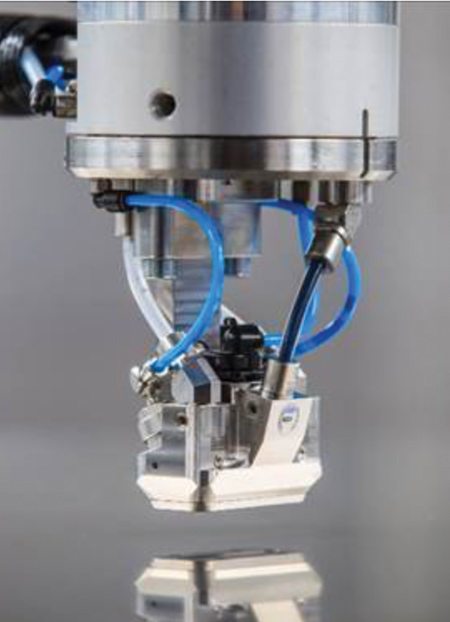

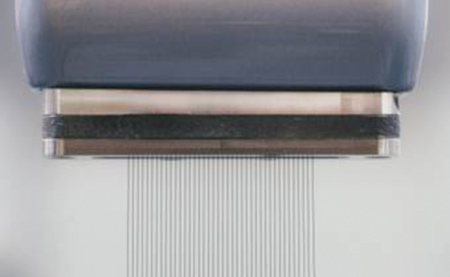

The EcoPaintJet applies parallel paint jets using a nozzle plate.

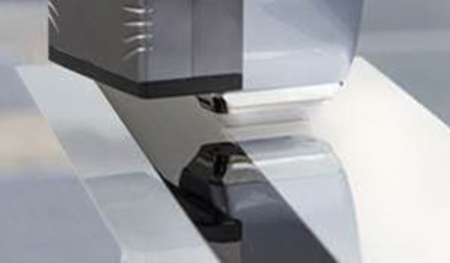

Precise painting paths enable surface painting and coating with high edge definition.

In almost every industry sector, the number and diversity of workpieces being coated are growing. To be able to paint these diverse components with greater efficiency, Dürr has developed a technique that applies paints over large areas or in simple patterns with high edge definition and no overspray. The EcoPaintJet applicator is available for the general industry in an easily integrated set. Paint company Adler has developed paints tailored to the application technology.

"In shipbuilding, electronics manufacturing and other industry sectors, product and component surfaces are coated to protect them or add color," said a company spokesperson. "This previously involved a great deal of effort if the coating had to be applied with high edge definition since the surfaces either need to be manually masked or film-wrapped. There is also a significant amount of waste, both in terms of adhesive tape and paint loss due to overspray. With the overspray-free application set from Dürr, both of these challenges are a thing of the past. EcoPaintJet, the innovative applicator contained in the set, is already successfully in use in automotive series production. Since 2019, the Dürr technology has made it possible to paint car roofs in contrasting colors with no masking."

More Options for Painting

The EcoPaintJet applicator delivers precise coating with no overspray. This increases coating efficiency and offers companies more options when it comes to product design and the transportation of goods. Instead of adhesive film, decorative surfaces can be protected for transport through the targeted application of a spray film and then easily removed at the destination. The technology also enables new options for the function and design of products. Additionally, the precise coating method means an item can have a weatherproof coating, for example, applied to one side and a differently colored application on the other side.

"The overspray-free application set enables application with high edge definition, fast color changes and a custom surface design," said Holger Beiersdorfer, Vice President Industrial Products at Dürr.

No Atomizer Air Means No Overspray

The most important component in the overspray-free application set is the paint supply, combined with the cleaning and pre-painting process. The EcoPaintJet controls this using three valves. The heart of the applicator is a nozzle plate that produces several dozen parallel paint jets depending on the design. These can be activated or deactivated at any given moment to start or interrupt the coating process. "Unlike painting processes involving spray guns or high-speed rotary atomizers, this process does not require any atomizer air. The overspray that must be filtered from the booth air in a complex process when using conventional methods therefore does not occur," said the spokesperson.

The width of the painting path can be adjusted by means of the applicator's angle of application. This enables a painting path from 30 mm to 50 mm in width. Narrower path widths can also be produced by adapting the nozzle plate. The desired coating thickness is controlled via the applicator speed and solid content of the paint.

All the Benefits in One Application

"Application techniques that save paint are particularly important when dealing with large surfaces," said the spokesperson. "Even with airless guns or high-speed rotary atomizers, up to a fourth of the material is lost. Recovering this paint is both time-consuming and energy-intensive, and only works with certain paint types. The so-called pouring technique, where the excess paint is collected in tanks, avoids overspray but does not permit fast color changes. Other surface design options such as applying films or decorative strips often mean a high level of manual effort."

"Dürr technology eliminates all the disadvantages of the individual methods and makes painting faster, more cost-efficient and more environmentally friendly in all industry sectors. This makes our technology attractive even in scenarios where an automated painting method was not previously conceivable," said Beiersdorfer.

Together with Dürr, Austrian paint manufacturer Adler is promoting the new application technology by developing colorless and pigmented coating solutions that, in addition to the usual paint requirements, are precisely tailored to the special features of this technology. "For this visionary application technology, we developed innovative, environmentally friendly, water-based products that deliver maximum durability and at the same time visual individuality for more than just sheet material," said Dr. Albert Rössler, CTO at Adler.

For more information contact:

Dürr Systems, Inc.

26801 Northwestern Highway

Southfield, MI 48033

248-450-2000

durrsystems@durrusa.com

www.durr.com