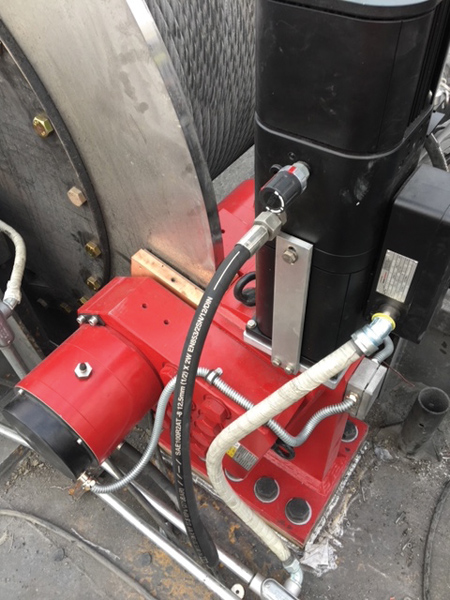

The Pintsch Bubenzer SF emergency brake acts directly on the ladle crane's drum, eliminating any chance of drivetrain failure causing a dropped load on a critical lift crane such as a hot metal or ladle crane.

Pintsch Bubenzer offers high performance disc and drum brakes for steel cranes and other severe duty applications. "End users of overhead cranes, particularly in the steel sector, should consider the safety benefits of installing emergency brakes, especially in environments where critical lifts are commonplace," said Mike Astemborski, Regional Sales Manager at Pintsch Bubenzer. "Fewer than 10% of cranes in the steel sector, including new ones, are fitted with emergency brakes in the U.S."

Nucor Corporation recently retrofitted cranes at a number of its locations. "We have installed Pintsch Bubenzer brakes on our hot metal cranes," said Jeff Johnson, Crane and Mobile Lead at Nucor Steel Utah. "This has created redundancy in case of a gear train failure. This is a very cost-efficient solution to provide more safety in our production environment-and it can be accomplished in a short period of time."

"In simple terms, a motor drives a gearbox that rotates a rope drum during lifting or lowering operations," said a Pintsch Bubenzer spokesperson. "On the majority of the installed overhead cranes in the U.S., a brake is only connected to the motor, meaning it is beyond the point of failure in many instances. Emergency brakes that connect to the winding drum itself can provide an additional safeguard and keep the load securely on the crane hook."

"All too often, a major incident leads to an investigation that exposes the lack of an emergency brake-but then it is too late," said Astemborski. "We need to continue to educate steel and other professionals to specify emergency brakes at the earliest stage of dialog with a crane manufacturer."

Nucor's Johnson concluded, "Pintsch Bubenzer has designed these systems to be compact units that need very little alteration to the existing layout of the hoist and trolley area. I feel that together we have a very good solution that will provide us years of trouble-free service."

For more information contact:

Pintsch Bubenzer USA LLC

Bartles Corner Business Park

8 Bartles Corner Road, Suite 102

Flemington, NJ 08822

908-237-9400

info@pintschbubenzerusa.com

www.pintschbubenzerusa.com