TrackMotion is a modular automation system that complements EMAG's modular machines.

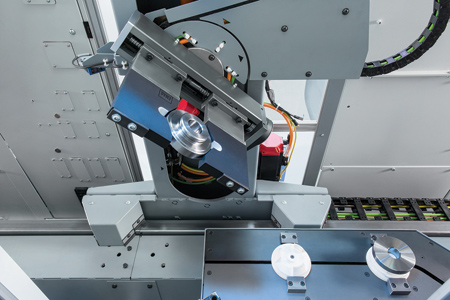

With the TrackMotion automation system, a TransLift unit travels through the machines on a rail.

The TrackMotion automation system basically consists of just two components: the track-or rail system-and the TransLift lift and turnover trolley that moves along this track.

EMAG has introduced its TrackMotion automation concept, a technology designed to provide the same high levels of flexibility, modularity and productivity as the company's modular machines.

TransLift, a lift and turnover trolley with programmable electric gripper, moves rapidly from one point to the next on a rail. The TransLift travels 150 m/min, swiftly transporting components back and forth between the machines and parts storage facility. "EMAG's TrackMotion automation system reflects a new mindset when it comes to automation-a way of thinking where the focus is on the individual component," said a company spokesperson.

Putting the Component on the Rail

The TrackMotion automation system basically consists of just two components: the track-or rail system-and the TransLift lift and turnover trolley that moves along this track. It is the TransLift that also makes this system so flexible, by not only transporting parts, but it can also turn workpieces and is equipped with a Z-axis that enables a stroke of up to 650 mm (depending on the version). This allows the use of stackers when supplying and discharging parts, or even the use of measuring and marking stations with different heights along the track.

The rail is positioned to the rear of the machines, directly behind the machining area. To make this possible, the energy container of the modular machines was offset from the rest of the machine body. The resulting "tunnel" behind the machines now serves as a location for swiftly transporting parts on rail. The tight arrangement of automation and machine means production systems can be set up in very small spaces.

Modularity Along the Entire Line

Just like the modular machines, the TrackMotion automation system is also a modular solution: the rail system comprises four different tracks at lengths of 2,400 mm, 1,200 mm, 600 mm and 300 mm each. Standardized end components, each containing the electric motors responsible for the TransLift's horizontal motion, are attached at the start and end of the rail system. The TransLift itself is available in two variations, each derived from the workpiece range of the modular machines. The e-gripper can be easily programmed to adjust to the respective diameter of the given workpiece.

The two modular systems not only complement one another in terms of construction. The modified interfaces, which can be centrally accessed through the machine control unit, also make it easier to set up the entire system. This enables the TransLift to receive information about the workpiece to be transported (for example, its diameter) directly from the machine control unit, and is then programmed accordingly.

The component defines the size, quantity and technologies required for the machines. The TrackMotion automation system is then adjusted to the length of the production system and the component diameter. "In practice, of course, it is not quite as simple as depicted here. It is, however, significantly easier than comparable solutions using conventional automation approaches," said the spokesperson.

Systematic Production

A complete production system with TrackMotion consists of three units that dovetail: the modular machines, the TrackMotion automation system and the supply and discharge belts. Acting as component storage sections, these belts can be laid flat if large workpieces are involved, or used three dimensionally as "stackers" for smaller workpieces. The latter variation offers particularly high performance in very small areas, affording the possibility of temporarily storing several hundred workpieces. The machines themselves are usually equipped with L-shuttle automation, which is used for suppling parts to and discharging parts from the pick-up station. Because only a small number of workpieces are being moved throughout the entire system, the status of every workpiece can be tracked at all times. This makes quality management much easier, since parts with deviating values can be easily identified.

For more information contact:

Kirk Stewart

Vice President of Sales

EMAG L.L.C.

38800 Grand River Ave.

Farmington Hills, MI 48335

248-996-4703

kstewart@emag.com

www.emag.com

SOUTHWEST

TX, LA

Eric Klenner

Regional Sales Manager

EMAG L.L.C.

248-595-1530

eklenner@emag.com

TX, OK, AR

Glenn Wise

Regional Sales Manager

EMAG L.L.C.

248-756-1641

gwise@emag.com

NM

Shane Cross

Regional Sales Manager

EMAG L.L.C.

248-207-5365

scross@emag.com

SOUTHEAST

MS

Eric Klenner

Regional Sales Manager

EMAG L.L.C.

248-595-1530

eklenner@emag.com

AL, GA, FL, NC, SC, E. TN, VA

Dave Fitzgerald

Regional Sales Manager

EMAG L.L.C.

248-595-1117

dfitzgerald@emag.com

W. TN

Mark Comeaux

Regional Sales Manager

EMAG L.L.C.

248-938-2097

mcomeaux@emag.com

NORTHEAST

W. PA, WV

Mark Comeaux

Regional Sales Manager

EMAG L.L.C.

248-938-2097

mcomeaux@emag.com

NY, PA, DE, MD, NJ, CT, RI, MA, VT, NH, ME

Kevin Gadde

EMAG L.L.C.

248-938-2430

kgadde@emag.com

Portions of NY and PA

Jeff Moore

Regional Sales Manager

EMAG L.L.C.

519-835-8425

jmoore@emag.com

MIDWEST

OH, KY, S. IN

Mark Comeaux

Regional Sales Manager

EMAG L.L.C.

248-938-2097

mcomeaux@emag.com

N. IN, W. MI

Peter Vandersluis

Regional Sales Manager

EMAG L.L.C.

616-307-7401

pvandersluis@emag.com

E. MI

Jeremy Elder

EMAG L.L.C.

248-962-8963

jelder@emag.com

ND, SD, NE, KS, MN, IA, MO

Bill Konetski

Regional Sales Manager

EMAG L.L.C.

612-804-0857

bkonetski@emag.com

IL, WI

Kirk Stewart

Vice President of Sales

EMAG L.L.C.

248-996-4703

kstewart@emag.com

WEST

WA, OR, CA, NV, ID,

MT, WY, UT, CO, AZ

Shane Cross, CMTSE

EMAG L.L.C.

248-207-5365

scross@emag.com