DMG MORI considers the automation of its machine tools to be the decisive foundation of the digital factory.

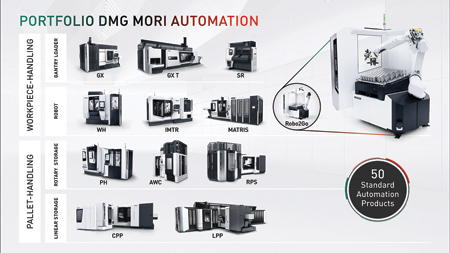

DMG MORI automation solutions.

Processes can be quickly and easily created with the Robo2Go 2nd Generationl, even without any knowledge of robot programming.

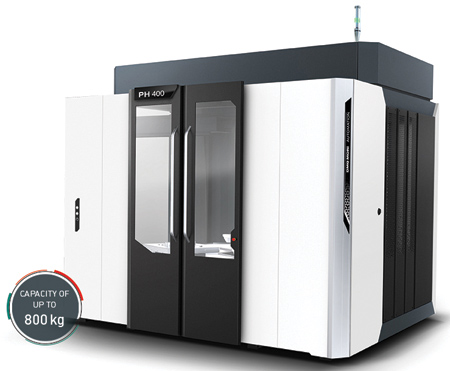

With a load capacity of up to 800 kg, the PH 400 in the DMG MORI portfolio is a suitable complement to the rotary magazine.

With flexible workpiece handling and palette automation systems, DMG MORI supports its customers on their path towards autonomous manufacturing.

Robo2Go 2nd Generation, PH 400

The Robo2Go 2nd Generation allows flexible workpiece handling on lathes. It can be operated on the CLX and CLX series turning centers as well as the turn and mill complete machining centers from the CTX TC series. The flexible robot automation solution is easy to operate via new software. The processes can be directly created with the Robo2Go 2nd Generation based on predefined program modules, and without any knowledge of robot programming. This means that teaching a new workpiece takes less than five minutes, making the Robo2Go 2nd Generation a flexible solution for small- and medium-sized batches.

DMG MORI has expanded its palette automation portfolio with the new PH 400-a suitable addition to the rotary magazine. This means that the DMU monoBLOCK and duoBLOCK series can now also be loaded with large palettes. The load capacity of the PH 400 is 530 kg in the version with 12 palettes and 800 kg if designed for six or eight palettes. With maximum workpiece dimensions of o850 mm diameter and 1,000 mm height, the PH 400 is an ideal automation solution for the DMU 80 P duoBLOCK and DMU 90 P duoBLOCK.

Palette handling systems are a part of the DMG MORI automation portfolio, which includes a total of 50 solutions in the area of workpiece and pallet handling systems. The latter are additionally divided into linear and rotary magazine systems, whereby the workpiece handling systems are available in robot or portal loading variations.

Modular Automation Solutions

With an integral approach, Joint Venture DMG MORI HEITEC is a supplier of modular, coordinated automation solutions. DMG MORI HEITEC supports DMG MORI in the development and realization of flexible automation solutions, such as workpiece handling. The automation expertise for pallet handling is directly integrated into the production plants of DMG MORI. The interplay between engineering from the DMG MORI production plants and automation expertise on the part of DMG MORI HEITEC provide the user with a customized, integrated solution from a single source. "In essence, we implement modular manufacturing cells and systems on the basis of a building block system, which allows them to be individually set up and customized," explained Kai Lenfert, Joint Managing Director of DMG MORI HEITEC GmbH together with Markus Rehm. This is particularly beneficial for small and medium-sized companies. DMG MORI HEITEC is focused on problem solving solutions and long-term value creation.

It is also about incorporating automation solutions throughout the entire production process. Lenfert explained: "A customer who develops an automated system for unmanned nightshift must also be capable of making available the required resources beforehand and during further processing." The more complex the task, the more detailed the planning needs to be for the system and, above all, integrated into value creation.

Digital Engineering

Due to the direct interaction with the DMG MORI plants, DMG MORI HEITEC can plan every automation project very specifically and optimize it for the customer based on virtual mapping in real time. Digital engineering with the depiction of real plants and machines through the digital twin and the analytical predictability of events are seen by DMG MORI HEITEC as an important building block for networked and intelligent production. Specific component programs can be run virtually for the customers prior to installation. This creates a high degree of investment security for the customer, provides fast installation and commissioning on site and allows a fast production start. The cycle times can be reduced by up to 80% in this way. Above all, equipped with knowledge gained from the virtual results of the digital engineering, the customer can already precisely assess during the decision-making phase how the system will affect the process chain and what the company may potentially need to do to guarantee efficient operation of the system and its entire production process.

For more information contact:

DMG MORI - Americas Headquarters

2400 Huntington Blvd.

Hoffman Estates, IL 60192

847-593-5400

Service Hotline:

855-DMG-MORI (364-6674)

www.us.dmgmori.com