Machine operator Günter Schulz with the Hermle C 22 UP 5-axis machining center in the tool and moldmaking division of WMF Group GmbH.

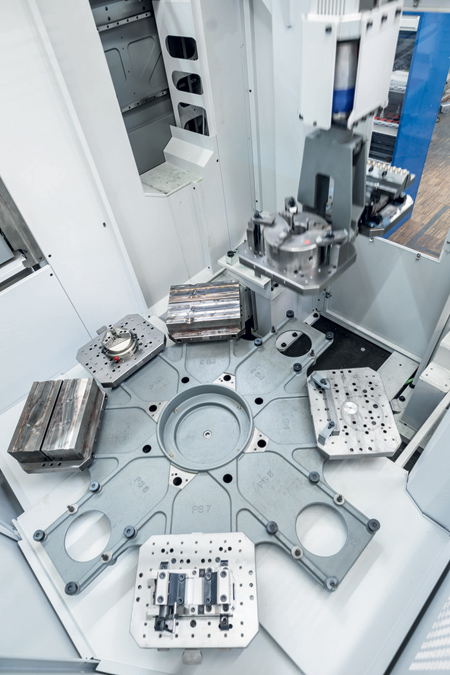

Top view of the 8-fold rack storage of the 11-fold pallet changer PW 150 with eight pallets in rack storage, two pallets in the changer (top right) and one pallet changer in the machine.

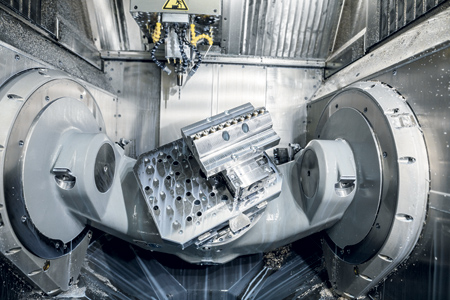

The working area of the C 22 UP machining center. The swiveling rotary table measures 320 mm in diameter (axes A and C) for 5-axis complete/simultaneous machining of tool components in a single set-up.

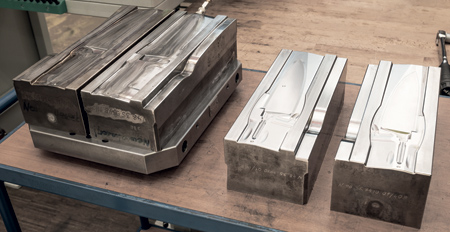

A forging die (upper and lower tool) on the left without adapter plate, clamped directly onto a pallet, fixed in place with two dowel pins and clamped with four screws; and on the right as a completely machined die.

(l-r) Axel Spadinger, Head of Tool Engineering & Making; Hans Brühl, Part Production and Tooling Technician; and Günter Schulz, machine operator, all from the tool and moldmaking division of WMF Group GmbH.

The C 22 UP machining center from Hermle is at the very heart of WMF Group's die and tool shop.

With its standardization strategy and the C 22 UP machining center from Hermle, the tool and moldmaking division of the WMF Group has streamlined its die and tool production processes and increased productivity.

At the WMF Group's Geislingen, Germany, headquarters and nearby Hayingen plant, more than 2,200 employees are engaged in the development and production of high-quality cookware and cooking knives. Many of these products are still manufactured through the primary and secondary forming of sheet metal blanks. The WMF Group manufactures most of the required tools in-house at its own tool shop.

"For about 30 different knife models alone, we use between 100 and 150 die tools, each consisting of an upper and a lower tool made of hardened hot-forming steel," explained Hans Brühl, Part Production and Tooling Technician at WMF. To ensure consistent high product quality, the mold makers have to rework the tools after roughly 3,000 strokes. This involves precisely milling and removing approximately 0.5 mm of material, a process that is possible up to 15 times with the dies. "In the past, we performed all of these milling and finishing operations on an HSC (high-speed cutting) milling machine," continued Brühl. "However, this machine could only accommodate two dies at a time, which then had to be processed successively and in several time-consuming set-ups. As knife production in Hayingen increased, more dies were obviously needed and this led to capacity shortages."

During a machine evaluation process-which included a series of tests to assess contour accuracy, precision and surface quality and to determine whether the specification of significantly reducing machining time for refinishing had been accomplished-the Hermle C 22 UP 5-axis machining center come out on top. "A machining process, developed together with Hermle, led to some extraordinary results," said a WMF Group spokesperson. "Not only was the desired reproducibility of contour accuracy and surface quality achieved, but the machining time was also reduced considerably. Due to the equipment of the C 22 UP machining center, featuring an 11-fold PW 150 pallet changer, it is now also possible to rework the dies automatically, in other words during the night and at weekends. This means additional capacity is now available for processing internal and external orders."

The fact that the WMF Group's tool and moldmaking division was able to achieve new levels of productivity is due in part to standardization of the dies. In addition, a self-developed pallet and workpiece clamping system with 4-fold bolting directly to the pallet, along with the automation provided by the PW 150 pallet changer, have allowed machining to become significantly more efficient.

Axel Spadinger, Head of Tool Engineering & Making at WMF Group GmbH, said, "We were able to reduce the machining time by 50% and more when refinishing the dies. Since this work is generally carried out at night and over the weekend, we can therefore use the C 22 UP machining center very flexibly during the day for all other machining operations. Combined with our expertise in tool and moldmaking, we are thus in a position to meet external customer needs on time."

For more information contact:

Hermle Machine Company, LLC

5100 West Franklin Drive

Franklin, WI 53132

414-421-9770

info@hermleusa.net

www.hermleusa.net