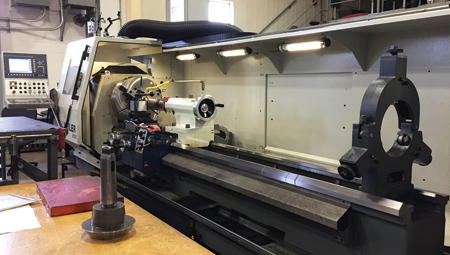

WEILER E-70 turning a Hydroheater component

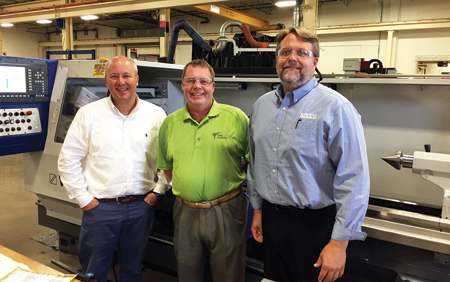

(l-r) Jim Zaiser, President, Hydro-Thermal; Mike Weller, Weller Machinery; Mike Johnson, Manufacturing Engineering Manager, Hydro-Thermal

World Headquarters for Hydro-Thermal, winner of the 2016 Wisconsin Manufacturer of the Year (WIMOTY) Award

Hydro-Thermal, a developer and manufacturer of direct steam injection heaters known as Hydroheaters, needed to replace an outdated machine. Rigidity, flexibility and output consistency were the major requirements, plus Hydro-Thermal wanted a machine that would be familiar to its machinists and not require excessive training. Better adaption to job requirements was also something Hydro-Thermal hoped to achieve.

Jim Zaiser, Hydro-Thermal's President and CEO, along with his evaluation team, made the decision to purchase a WEILER E-50/165 x 2M Big Bore, and it was installed in early January 2017. The E-50 complements the existing E-70, purchased from Weller Machinery in 2012. The main catalysts for the decision to purchase another WEILER were the simplicity and rigidity of the German-engineered lathes.

"Quality is paramount to the function of our valves," said Zaiser. "When I was introduced to the machine, I wanted to see it from the base up. I visited the plant in Germany and saw my machine being assembled with the precision I expect. With a personal tour from Mr. Weller, I even incorporated new ideas from their plant into ours. The machine is a quality investment."

WEILER E-70

Hydro-Thermal was first introduced to WEILER by distributor Weller Machinery. Mike Weller recognized Hydro-Thermal's need for a machine that was easy to operate, flexible and above all, precise. Hydro-Thermal was machining parts with 20-25" diameters and a HRC of 60. "The E70 was the perfect machine for Hydro-Thermal's operation," said Weller. "The size and type of their parts match perfectly with the strength of the WEILER lathe. The machines are built to last and well worth the investment. Additionally, Hydro-Thermal produces a large variety of parts in very low quantities with ever changing schedules-the ability to rapidly move from one job to the next was huge."

WEILER E-machines are capable of manual or programmable modes and are easy to learn and program. With the WEILER developed control software, Hydro-Thermal's machinists did not need excessive training. The E-70 is used at Hydro-Thermal every day in multiple shifts.

The E-70 machines components that require stringent accuracy despite having rough and hardened surfaces. This type of machining results in long run times, which allows the machinist to perform other duties.

WEILER E-70 features include:

- Distance between centers: 39" - 236"

- Swing over bed: 28.35"

- Swing over cross slide: 16.93"

- Cross slide travel: 16.14"

- Width of bed: 18.90"

- Drive power at 60/100% duty cycle: 50/40 HP

- Max. torque at spindle: 2,300 ft-lbs.

WEILER E-50/165 x 2,000 mm

Hydro-Thermal purchased and installed another WEILER lathe, an E-50, near the E-70 so one machinist could utilize both machines. While the E-70 is running a longer program cycle, the machinist sets up and cuts a different part on the E-50. The E-50 also affords Hydro-Thermal the ability to reassign work to a better suited machine.

"Previously, we were trying to machine parts on lathes for which they were not designed to handle," said Mike Johnson, Hydro-Thermal Manufacturing Engineering Manager. "The WEILER E-50 allows us to delegate work to a better suited machine. We also purchased the bigger bore so we could properly hold entire parts and improve surface finishes. We have found that the E-50 can machine our smaller parts 40% more effectively than a manual lathe or a lighter duty lathe."

In the short time that the E-50 has been installed, the Hydro-Thermal team is already seeing its value. The E-50 3-jaw bar chuck is better suited for Hydro-Thermal's smaller parts, which has freed up time on manual and semi-automatic machines. The E-70 is able to machine longer and bigger parts more efficiently, so the smaller parts that were on the E-70 have been transferred to the E-50 HD, allowing the E-70 to focus on the bigger parts that require greater accuracy and longer cycle times. The workload on the E-50 HD will continue to grow as Hydro-Thermal's machining repeatability and consistency continues to excel. The machine was purchased with a boring bar, and the through-bore capability provides added functionality for Hydro-Thermal.

WEILER E-50 features include:

- Distance between centers: 39"/78"

- Swing over bed: 22.4"

- Swing over cross slide: 13.4"

- Cross slide travel:13.4"

- Width of bed: 13.8"

- Drive power at 60/100% duty cycle: 27/23 HP

- Max. torque at spindle: 960 ft-lbs.

Weller Machinery and WEILER worked together to design and configure the right options for Hydro-Thermal. The standard Multi Suisse tool post was replaced with a four-way quick change Parat tool post that indexes and repeats to 0.0002", eliminating constant measuring.

Hydro-Thermal was recently awarded the Wisconsin Manufacturer of the Year Award for medium-sized companies.

For more information contact:

Hydro-Thermal

400 Pilot Court

Waukesha, WI 53188

262-548-8900

www.hydro-thermal.com

WEILER North America Corporation

1121 Park West Blvd. Ste B #106

Mount Pleasant, SC 29466

843-810-3839

info@weilerusa.com

www.weilerusa.com

MIDWEST ONLY

Weller Machinery Company

N114 W18605 Clinton Drive

Germantown, WI 53022

262-251-1500

sales@wellerusa.com

www.wellerusa.com