Marking AM Parts

November 1, 2017

XL-Box laser marking workstation

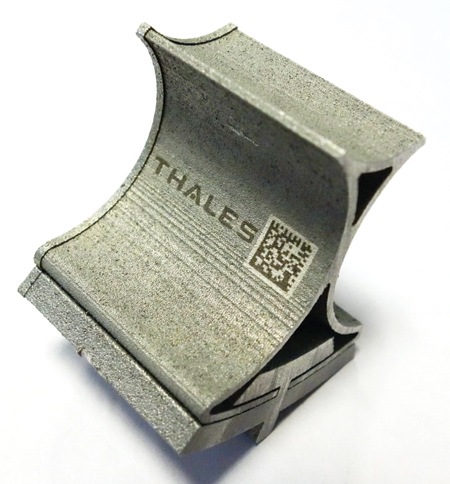

Datamatrix code marking on aluminum parts made by metal AM

SIC Marking offers marking systems for parts made by 3-D printing/additive manufacturing (AM). Once customer, Thales, has invested in 3-D printing and created a competence center in Morocco. The parts developed with AM are mainly made of aluminum and titanium.

Thales Morocco ensures traceability by marking data matrix codes on these components using SIC Marking's laser workstations. A 20 or 50 W fiber laser is incorporated into an XL-Box laser marking station, which offers the following features:

For more information contact:

SIC Marking USA

137 Delta Drive

Pittsburgh, PA 15238

412-487-1165

info@sicmarkingusa.com

www.sic-marking.com

< back