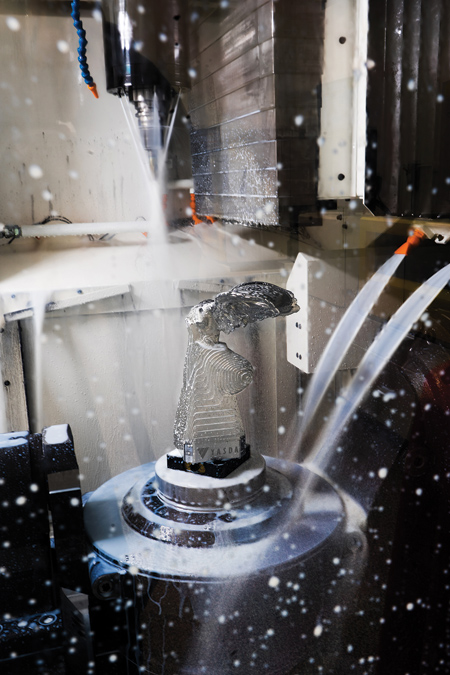

Production of the Nike of Samothrace on the Yasda PX30i. (photo credit: Brandon Harmon)

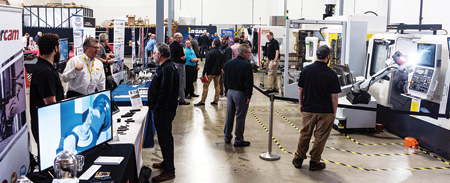

Methods Product Manager Darren Wall discusses the 5-axis Methods MB650U with attendees.

The showroom at Methods Gilberts, IL, location.

Attendees take in vendors and a row of Methods automation solutions.

Methods Machine Tools recently hosted a Methods Machine Fest at the company's Gilberts, IL, location.

Methods displayed its portfolio of machines and engineering capabilities. Combined with tooling, workholding, chip management and accessories providers, attendees had a one-stop shop for their current and future production needs.

"That is the whole idea of Methods Machine Fest," said Mike James, Methods General Manager for Illinois and Wisconsin. "We have been operating in this territory since 1996, but our industry has changed a lot since then. We know customers and buyers increasingly want one provider to handle their full machining, engineering, automation and support needs. We aimed to show them what is possible when they work with us."

Methods upsized to its current location after spending its first 25 years locally in Elgin, IL.

"The new location is a significant improvement. Not only are we able to scale our production, build more turn-key solutions and house more machine and parts inventory, we can also welcome the sizable crowds we saw during Machine Fest," James said.

Front and center in the Methods showroom were the Nakamura-Tome SC-100X2, NTY3-150 and MX-100 multitasking centers, the 5-axis Methods MB650U, FANUC RoboCut, three sizes of FANUC RoboDrill and the Yasda PX30i. Rounding the corner brought attendees to Methods automation solutions, including a RoboJob collaborative robot (cobot) tending a Nakamura-Tome WY-100II, two types of cobots in the Methods Job Shop Cell Collaborative and Job Shop Cell Pro integrated with the RoboDrill, and a 5-axis OKK VCX-500 with an Erowa pallet changer.

Many shops today juggle the dual pressures of staffing challenges on one hand, and the desire (and need) to scale production on the other," said Zac Borost, Methods Sales Manager. "At the intersection of these business priorities is where our automation delivers value. Our solutions are designed end-to-end for reliability and ease of use so operators quickly achieve return on investment and grow their businesses.

Methods recently announced that it formally became the sole partner representing OKK machines throughout North America.

OKK is a powerhouse brand for this market, James said. Whether you are in agriculture, die/mold, automotive or beyond, these platforms have the size, rigidity and operational reliability to tackle any job.

For more information contact:

Methods Machine Tools

70 Prairie Parkway

Gilberts, IL 60136

www.methodsmachine.com