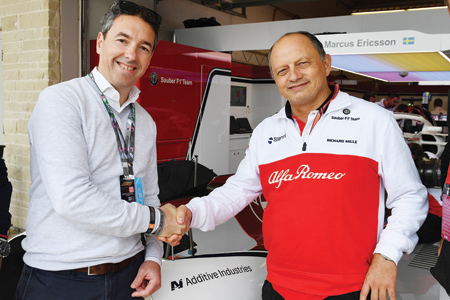

(l-r) Daan Kersten, CEO of Additive Industries; and Frédéric Vasseur, Team Principal Alfa Romeo Sauber F1 Team and CEO Sauber Motorsport AG

Alfa Romeo Sauber F1 Team and Additive Industries announced that they will extend their three-year Technology Partnership to five years. The Alfa Romeo Sauber F1 Team recently took delivery of its third MetalFAB1 system within a year and expanded its second system with an additional build chamber, or Additive Manufacturing Core, to expand the productivity.

Frédéric Vasseur, Team Principal Alfa Romeo Sauber F1 Team and CEO Sauber Motorsport AG, said, "We are pleased to be extending our current partnership with Additive Industries, and to introduce a third MetalFAB1 3-D printing system to our facilities. Not only do we aim to develop our production of parts for Formula One further, but we are also expanding our competences and activity in our third-party businesses. Building on the successful collaboration we have had so far, we look forward to working with Additive Industries and making further progress in our shared projects."

Christoph Hansen, Head of Technical Development at Sauber Engineering AG, added, "After an in-depth evaluation of all systems, we found Additive Industries' MetalFAB1 to be the only true industrial system available on the market. Their level of integration and automation allowed us to implement the technology very fast and with only a small team of experts. The MetalFAB1 system is easy to use and has high consistency across the build chambers and between systems, allowing us to schedule the workload flexibly over the three systems."

"For Additive Industries, this partnership extension with the Alfa Romeo Sauber F1 Team confirms the acceleration in industrial additive manufacturing (AM) that we are aiming for. Repeat sales in such a short time are the best compliment for our team, both for the system design and 3-D metal printing process, and also for our customer support team, which works closely with the Alfa Romeo Sauber F1 Team to reach the highest productivity in the market today. We are both proud and grateful for such a partnership," said Daan Kersten, CEO of Additive Industries.

For more information contact:

Additive Industries

www.additiveindustries.com