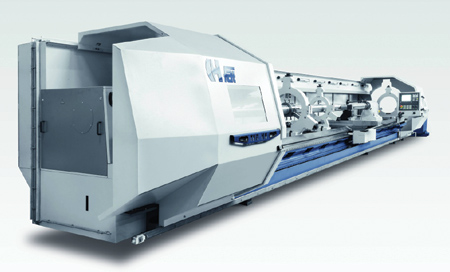

Swing Lathes with Solid Bed Design

January 1, 2019

TUR1350MN/CNCx12M; 53" x 472" BC

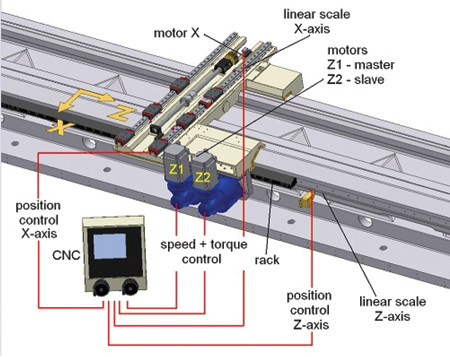

TUR-MN/CNC: Z-axis drive (rack and dual pinions), X-axis linear bearings (6 large trucks) with X and Z linear scale direct feedback systems

TUR1350MN/CNCx4M: 53" x 157" BC, 4 axes (XZCY)

Toolmex Lathes has announced the next generation of mid-size TUR European built lathes: TUR1150MN, TUR1350MN and TUR1550MN. All feature the heavier solid floor to front V-way bed, plus more choices of: turning diameters (45" - 61" over bed and 51" - 66" in gap area), length between centers (BC) 78" - 992", load capacities 24,000 - 50,000 lbs. BC, main drive options from 50-100 HP and spindle bores 5" - 25".

One can choose either a FANUC or Siemens control in 2-4 axis configurations. The solid cast bed is an enhanced design with extra wide ways, a massive front V-way for greater stability and accuracies, plus a low profile bed for easy work loading and unloading. The solid bed increases rigidity, assuring improved performance. TUR massive front V way is ~7" wide to take high cutting forces.

Another key feature of this TUR-MN series is the rack and dual pinion Z-axis drive (no ball screw) with a direct feedback scale. This Z-axis drive design eliminates typical long ball screw sag and runout issues, while allowing longer beds (distance BC) and faster rapid traverse rate with less backlash and wear (compared to a ball screw).

Key TUR-1350MN/CNC solid bed features:

- Heavy full length, low profile bed supports the lathe to the foundation; 53" x 157" BC weights ~ 51,000 lbs.

- Increased rigidity and heavier load capacity of 24,000 lbs. BC or 50,000 lbs. BC (without a steady rest)

- Improved operator access to work and tooling: faster set-ups, easier loading and unloading

- The optional (TUR-4SMN series) offers the solid and 4-way/3 shear bed version for "turn through steadies" machining

- 236" BC and longer with rack and dual pinion drive plus direct linear feedback system

- Wider front V-way reduces "fish tailing" in +/-Z traverse (tighter tolerances when boring and turning)

- TUR beds are built extra wide: 40" (2-way bed) increases contact, stability and performance

- Bed has a built-in front chip conveyor ideally located to improve chip collection and disposal

- Pre-cast gap section allows extra-large disc type parts 51" - 66" dia. to be turned.

For more information contact:

Tom Kob

Toolmex Lathes

2015 S. Mitchell Blvd.

Schaumburg, IL 60193-4543

847-301-3700

machinesil@toolmex.com

www.toolmexlathes.com

< back