Vertical Turning Centers with High Efficiency and Performance

January 1, 2019

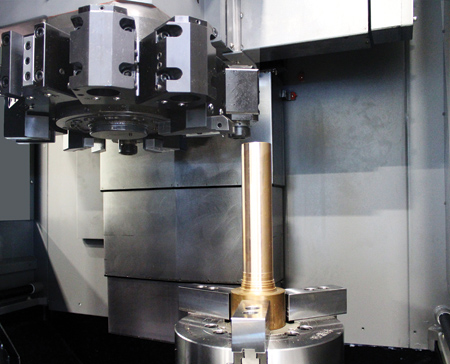

FFG DMC DL 60VLM vertical turning centers

FFG DMC continues to build upon its range of high performance vertical CNC turning centers-DL 40V, DL 60VL[M], DL80VL[M] and DL100VM-with its latest product offering, DL 60VLM with a 12" chuck size.

The DL 60VLM offers high efficiency, high productivity vertical CNC turning and uses many precision components including a high torque main spindle motor for high speed and heavy cutting applications. The bed and column and wide box guideway structure provide rigidity and accuracy. The X, Z-axis is very wide and thick guideway and six faced slide way provided by high frequency heat treatment and fine grinding. This is available for long time cutting and heavy duty cutting. They are suitable for rough of finish machining of general industry components.

"DL 60VLM provides the guide type which is top/bottom guide way supporting saddle for enhanced rigidity and guide way is close to spindle center line best in class precision machining," said a company spokesperson.

For more information contact:

David M. Valentine CMTSE

National Sales Manager

949-599-5833

valentine@cncsystems.com

www.cncsystems.com

Parts: parts@cncsystems.com

Service: service@cncsystems.com

< back