The WAAMpeller project uses PowerMill additive and subtractive technology to produce a nickel-bronze alloy ship propeller. Image courtesy of www.ramlab.com.

Autodesk Drive allows PowerMill project data to be viewed on cloud-connected devices.

PowerMill's Vortex roughing code now includes a "From Stock" option based on Adaptive Clearing

Autodesk offers PowerMill 2019. PowerMill is Autodesk's CAM solution for high-speed and 5-axis machining. "It offers a comprehensive range of strategies and powerful editing tools to provide efficient, safe and accurate machining, especially for companies that are using sophisticated CNC machine tools to produce complex shapes in challenging materials," said a company spokesperson. PowerMill is used in a wide range of industries but is particularly successful in mold, tool and die, complex aerospace and automotive applications.

The release of PowerMill 2019 focuses on three key areas of development:

- Enhancing existing functionality for high-efficiency machining

- Adding technology from the wider family of Autodesk software that can benefit PowerMill users

- Developing completely new technology to allow PowerMill to support new processes.

Additive Manufacturing

To meet the growing trend for CNC machine tools that offer both additive and subtractive capabilities, PowerMill 2019 provides a dedicated suite of additive strategies and simulation tools. These are specifically designed to solve the unique challenges of programming these hybrid machines. PowerMill can generate safe and efficient toolpaths to drive directed energy deposition (DED) processes that utilize wire-fed or powder-blown hardware.

These are not simply subtractive toolpaths in reverse, instead PowerMill offers specialized 3- and 5-axis programs that can be used to build entire components from scratch. Alternatively, localized features or surface coatings can be applied to existing parts, allowing components to be enhanced or repaired. With PowerMill, manufacturers have instant access to a vast library of subtractive manufacturing strategies, meaning critical features can be CNC machined where needed.

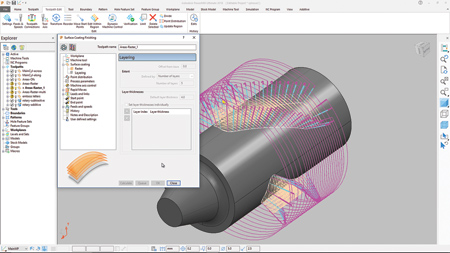

5-Axis Collision Avoidance

For 5-axis programming, PowerMill's collision avoidance tools have been further improved. A new "automatic tool-axis tilting" method for collision avoidance simplifies the programming of 5-axis machines. The new option provides a single solution that helps generate smooth and safe 5-axis motion for all model shapes and toolpath types, making it as easy to create 5-axis programs as it is 3-axis code.

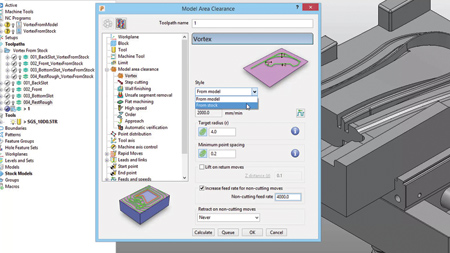

Vortex from Stock

"PowerMill's high-efficiency roughing strategy - or Vortex - was one of the first high efficiency roughing algorithms to hit the world of CNC machining," said the spokesperson. The 2019 release sees the inclusion of a new "From Stock" option that is based on the "Adaptive Clearing" technology provided in other Autodesk CAM software products.

This new option creates toolpaths with offsets that are based on both the shape of the part being produced and the stock being milled. The result is toolpaths that are considerably more efficient, with shorter machining cycle times and fewer tool retractions. In recent tests, carried out in Autodesk's Advanced Manufacturing Facility (AMF) in Birmingham, UK, a test mold was machined in P20 tool steel. The previous "From Model" option took 48 min 28 secs to complete. The "From Stock" option used the same tooling, feeds and speeds and yet produced this same part in 32 min 33 sec, a saving of 33%.

2-D Programming

For 2-D machining, PowerMill provides an improved workflow for the definition of open-sided pockets and bosses. These new, open, features are recognized by PowerMill's existing 2-D toolpaths, meaning tool entry and exit points are automatically positioned in sensible locations to avoid overloading cutting tools. In addition, PowerMill 2019 allows 2-D features to be created based on a selection of surfaces - reducing the time and effort needed to generate NC code.

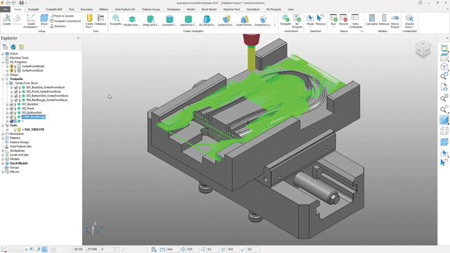

ViewMill Thickness Shading

PowerMill's stock simulation tool - ViewMill - has been enhanced to include a new "Remaining Material" shading mode. This helps CAM programmers to identify areas of un-machined stock quickly, to ensure parts are fully machined before being removed from the machine. The shading mode automatically identifies the maximum amount of stock left on a simulated part and provides dynamic slider bars to allow programmers to visualize the distribution of stock. This improvement aims to give manufacturers increased confidence that the parts are cut correctly and fully prior to being removed from the CNC machine table.

Machining Setups

PowerMill 2019 includes a new entity called "Setups," that allow programmers to better manage the synchronization between toolpaths and NC programs. This first version of Setups also provides tools to help manufacture parts that use multiple fixture offsets.

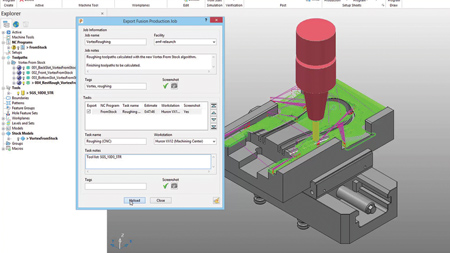

Send to Fusion Production

To improve collaboration between the programming office and the shop floor, PowerMill 2019 includes a direct interface to Autodesk Fusion Production, a cloud-based collaboration tool specializing in scheduling and tracking production and monitoring CNC machine utilization. PowerMill data, including NC code, set-up sheets and work instructions, can be shared with key project stakeholders using internet-enabled devices such as mobile phones and tablets. Fusion Production helps manufacturers to get an instant overview of the performance of their facility, allowing them to identify problems and avoid bottlenecks sooner.

Autodesk Drive

Like many Autodesk products, PowerMill now benefits from access to Autodesk Drive, a personal cloud storage site. Subscribers to PowerMill can save project data to a secure cloud and invite project members to collaborate and review the contents of their projects using any cloud-connected device. PowerMill models, tools, toolpaths and NC programs can be interrogated without the need for a PowerMill license.

Autodesk is offering a free, 30-day trial of PowerMill Ultimate 2019 at www.autodesk.com/powermill-free-trial.

For more information contact:

Autodesk, Inc.

5400 Meadows Road, Ste. 500

Lake Oswego, OR 97035

503-707-3600

www.autodesk.com/powermill