The SwissDECO G is available in four versions, (gang version - showcased at IMTS), SwissDECO GA (gang version with A-axis), SwissDECO T (turret version) and SwissDECO TB (turret version with B-axis), allowing manufacturers to choose the kinematic solution that best fits their needs.

Available in 25.4 mm or 36 mm, the SwissDECO G has up to 38 tool positions, 27 of which can be live tools.

"Highly productive, extremely flexible, automation ready and Industry 4.0-enabled, are the hallmarks of the new SwissDECO - a high-end multi-tasking lathe with a modular platform," said a Tornos spokesperson.

Available in four versions, SwissDECO G (gang version), SwissDECO GA (gang version with A-axis), SwissDECO T (turret version) and SwissDECO TB (turret version with B-axis), manufacturers can choose the kinematic solution that best fits their needs. Designed for economical production of complex parts, the SwissDECO is suitable for a wide range of growing industrial segments-including automotive, medical and dental, electronics and aeronautics-due to its latest-generation drive technology, tooling, rigidity and modularity. Solutions in the SwissDECO range are built on a common 36 mm base and designed and optimized with finite element method (FEM) analysis.

SwissDECO G

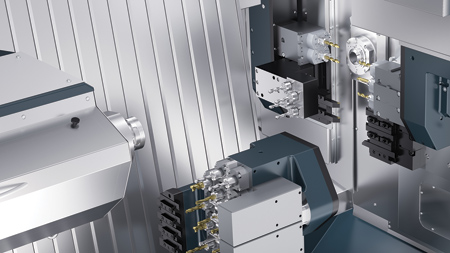

The SwissDECO G, with opposing gang, is equipped with nine linear axes. Equipped with a Z-axis for roughing and finishing operations, frontal operations and deep drilling, this enables operations in differential mode. The SwissDECO G features three independent tool systems. These machines can also be fitted with modular, pre-adjustable tool systems and devices. Due to its configuration, this solution allows fast chip-to-chip times. Available in 25.4 mm or 36 mm, the SwissDECO G has up to 38 tool positions, 27 of which can be live tools.

"These solutions are so well thought out that bar diameter will be the only real limitation for the SwissDECO, so the user can execute virtually any part with no constraints in terms of part complexity or material," said Philippe Charles, Tornos Head of Product Management Swiss-Type. "The SwissDECO line uses only the latest drive technologies, including the newest spindle motor technology and the highest torque 36 mm spindle on the market."

Integrated Autonomy

"With the SwissDECO range, this solution allows a great degree of automation, even when producing the most complex parts. Tasks traditionally requiring a human touch, such as cleaning, are minimized and others are eliminated due to the seamless integration of peripherals, including a high-end chip management system," said the spokesperson.

With its new Industry 4.0-ready human-machine interface (HMI), programming is a simple, intuitive process guided by icons on a touchscreen, so the user's learning curve becomes less challenging, even if the job at hand is extremely challenging. One example is the SwissDECO's automatic process optimization: once the machine is programmed, tool displacement is automatically calculated and optimized.

Autonomous Productivity

The potential for 24/7 autonomous production is engineered into the SwissDECO line too. The range is compatible with a wide selection of automation solutions, right out of the box, including Tornos' new Robot Cell i4.0.

"The Robot Cell i4.0, also available this year, is one single solution for cleaning, measuring and storing parts," Charles said. "It makes in-process machining correction and storage of as many as four batches of parts. So, it can turn up to four Tornos machines into a state-of-the-art production cell. Its closed-loop monitoring sends all machining corrections to the appropriate Tornos machine and all data is stored to provide full traceability, which is another hallmark of Industry 4.0-the factory of the future."

For more information contact:

Tornos US

840 Parkview Blvd.

Lombard, IL 60148

630-812-2040

info-us@tornos.com

www.tornos.us