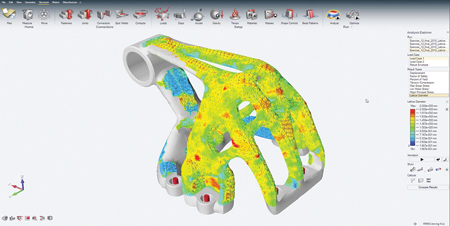

Structural simulation of mixed solid and lattice optimization results

Mixed solid and lattice optimization on a prosthetic human jaw

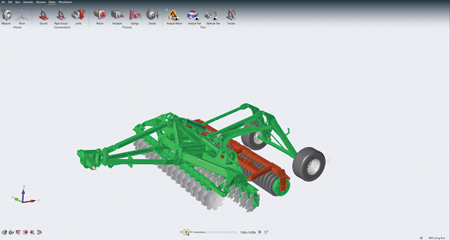

Assessment of complex mechanical systems for load generation system simulation

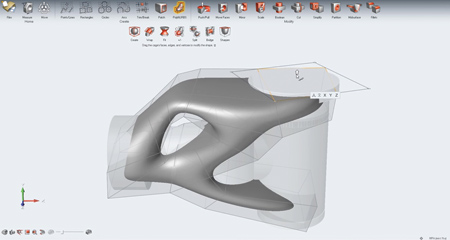

Create final solid geometry by automatically optimizing the fit of PolyNURBS CAD geometry to generative design results

Altair has released Inspire 2018 simulation-driven design software. "Available through its solidThinking channel partner network and directly to its HyperWorks user community, Inspire 2018 marks another milestone in Altair's leadership in generative design, optimization and simulation," said a company spokesperson.

"Inspire 2018 enables designers and engineers to leverage simulation in new and inventive ways to accelerate the development of high-performance, innovative products," said James Dagg, CTO for User Experience at Altair. "Inspire integrates well into large manufacturing enterprises for rapid simulation and lightweighting insights, and has an intuitive user experience that is suitable for small and medium-size businesses with little or no simulation experience."

Applied at the very beginning of clean-sheet design programs and for design exploration of current production parts, Inspire simulation-driven design software allows designers and engineers to:

- Assemble and simulate dynamic mechanical systems to automatically resolve loads on system components for optimization and analysis

- Generate weight-efficient design proposals unique to specified conventional or additive manufacturing (AM) processes with Altair's topology optimization technology

- Simulate the performance of competing design concepts for static loads, normal modes and buckling

- Directly export Inspire CAD geometry to 3-D printers to produce high-performance, quality parts.

Andy Bartels, Inspire Program Manager, explained, "In order to stay competitive while pushing the innovation envelope, simulation must drive the entire design process from the early concept design phase all the way through to production. We continue to add tools to make Inspire more beneficial to its users in each step of the design process."

Inspire 2018 includes new advancements to:

- Generate optimized lattice and mixed solid - lattice structures, visualize simulation results in 3-D and export lattice designs in .stl file format for 3-D printing

- View and interactively assign loads to load cases and import / export design loads in .csv file format with the new Load Cases Table

- Design for AM with overhang shape controls to help reduce overhangs to create more self-supporting structures

- Automatically optimize the fit of PolyNURBS CAD geometry to generative design results with the new PolyNURBS Fit Tool.

"Inspire 2018 is available to clients as an application software download and as a cloud-based offering," said Dagg. "Branded as Inspire Unlimited, the cloud offering of Inspire includes additional functionality such as secure data management, team collaboration tools and on-demand high-performance computing (HPC)."

For more information contact:

Altair Engineering Inc.

1820 E. Big Beaver Road

Troy, MI 48083

248-614-2400

www.altair.com/Inspire2018