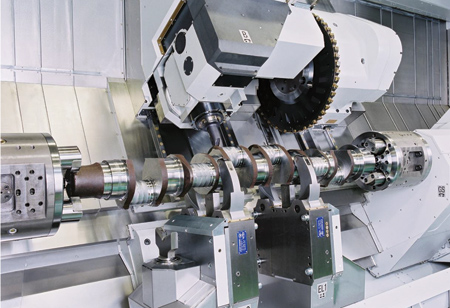

Niles N30MCMx3200 Crankshaft Machining Center

Niles N30MCMx3200 work zone

Niles-Simmons, a holding corporation company of the NSH Group, headquartered in Chemnitz, Germany, has received a contract from Continental Motors Group Ltd. (CMG), an AVIC International Holding (HK) LTD company.

Niles-Simmons, a holding corporation company of the NSH Group, will provide an advanced manufacturing solution to Continental Motors Group Ltd. (CMG) for the production of aircraft piston engine crankshafts at its new facility in Mobile, AL. CMG was searching for machines capable of processing any product, in any mix, at any time (AAA).

The Niles-Simmons Crankshaft Milling Center N30 MCM is based on the production proven MC-Series slant bed lathe. Niles uses a modular building-block system to configure the MCM to permit economical, flexible, high precision complete machining of crankshafts in one set-up.

This configuration includes two symmetrically arranged turning spindles. The main and counter spindles are electronically synchronized torque drives. The machine has two longitudinal cross slides, one with a powerful disk milling unit for rough and finish milling operations on crankshaft main and pin journals. The other cross slide is a universal turning-milling-drilling head.

"The milling disk along with the mill-turn spindle by Niles gave us the flexibility we needed to reach our goals by reducing processing time, number of operations and set-up time," said Martin Lee, Manufacturing Engineering Director. "The team at Niles responded quickly to our RFQ and worked diligently with us to arrive at the final solution."

Aircraft piston engine crankshafts produced by CMG also require deep hole drilling and special 90° heads to reach counter balancing features as well as standard milling and drilling of oil passages.

CMG Greenfield Factory

CMG has started the foundation work for its new manufacturing facility. The new facility will be nearly 275,000 sq. ft., with the majority being dedicated to advanced engine and parts manufacturing for all CMG product lines. It will be populated with new manufacturing equipment and include a special area designated for evaluation of new manufacturing techniques and processes, including additive manufacturing and automation.

Building a new factory is only one part of the $75 million plan to profoundly transform CMG and the way the company designs, manufactures, certifies and support products. CMG is also building a new customer and technology development infrastructure that will allow its team members to better focus on building customer satisfaction and develop innovative new products.

"CMG has been a big part of the local Mobile community for over 50 years and is pleased with the community support that allows us to renew our commitment to the region and our great team members for many years to come. The greenfield facility will modernize our manufacturing processes into a world class, high productivity, vertically integrated center of manufacturing excellence among the aviation cluster in Mobile, Alabama," said Michael Skolnik, Executive Vice President Global Operations.

For more information contact:

NSH Group

6255 Center Drive

Sterling Heights, MI 48312

www.nshgroup.com

Continental Motors

www.continentalmotors.aero