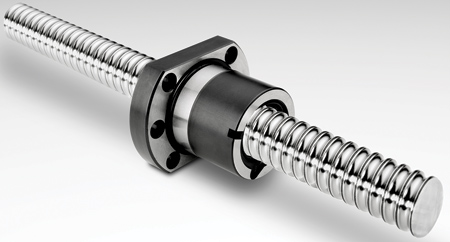

Thomson's FSI Style metric precision ball screw assemblies provide positional accuracy for applications such as large 3-axis structures, gantries, engravers, and laser and waterjet cutting.

Thomson Industries, Inc., a manufacturer of mechanical motion control solutions, has further enhanced its customer offerings in North America by utilizing its domestic manufacturing facilities to deliver its German-engineered metric ball screws with shorter lead times.

"As only two percent of all metric ball screws sold in North America are manufactured domestically, customers typically are forced to wait up to 10 weeks for metric ball screw deliveries," said a Thomson spokesperson. "Thomson's investment in domestic logistics allows orders to ship in only 1-2 weeks, reducing downtime, lead times and costs, and accelerating customer integration. This move also offers enhanced communication with support and services and the ability to rapidly prototype designs," said the spokesperson.

FSI Style metric ball screws are suited for applications requiring smooth motion and are DIN 69051 compliant, allowing them to be used in a wide range of laboratory, medical and mechatronic applications. These qualities, combined with the precision rolled solution, make them suited for large 3-axis structures.

"The high level of accuracy offered by FSI Style ball screws also allow them to be used in engraver/laser/waterjet cutting installations," said the spokesperson. These types of applications typically require P3/P5 accuracy, 75-100% duty cycle, harsh environments and reversing loads or dithering issues. FSI ball screw assemblies have molded rubber (NBR) seals in standard sizes o16 mm and above.

FSI Style assemblies range from 16 to 50 mm in diameter with leads from 5 to 40 mm - all with standard lead accuracies of ±23 µm / 300 mm.

For more information contact:

Thomson Industries, Inc.

203A West Rock Road

Radford, VA 24141

540-633-3549

Thomson@thomsonlinear.com

www.thomsonlinear.com