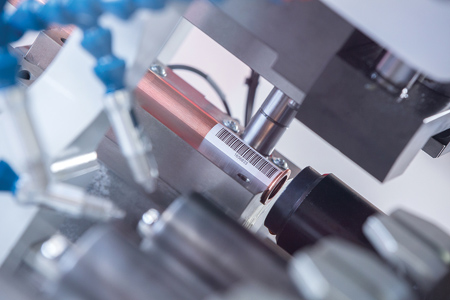

Prior to the end forming, the operation parameters are read via a barcode.

All tools of the REB 645 by transfluid are equipped with sensors (RFID).

The new tube forming machine REB 645 with automatic tool detection

transfluid has introduced an axial tube forming machine, REB 645, with automatic tool detection. Workpieces of a special end form geometry are often in demand. Whether for the initial production or repeated precision, ensuring exact parameters is necessary for efficient implementation of tube forming. transfluid has developed a solution with automatic tool detection for tube forming. The new axial tube forming machine, REB 645, allows for tube end forming with fast tool changes for complex geometries and extreme degrees of forming.

The starting point is a barcode scanning system. Using this system, the operation data of a tube with individual barcode can be easily read. For the purpose of end forming, all tools of the machine, which is equipped with six forming stations, have sensors (RFID). This ensures that the right program and the appropriate tools are available. If the automatic inspection unit detects a wrong tool, the operating panel with data memory displays this information immediately. Here, the identification for the correct tool for the change is indicated as well. Using the quick-connecting system of the transfluid solution with a fork for fixing and a locking bolt for securing the mount, the machine operator can directly change the tool and precisely perform the tube end forming afterwards.

The REB 645 allows the axial forming of tubes with diameters from 6 to 45 mm. By means of a servomotor, the tool sequence is positioned horizontally and vertically. In addition, rolling stations for specific forming processes can be integrated. Upon request, the machine can be equipped with electric or hydraulic numeric drives. In case of extremely short cycle times, these forming procedures can also be carried out gradually in transfer systems.

For more information contact:

Gerd Nöker

Managing Director Sales & Marketing

transfluid Maschinenbau GmbH

Hünegräben 20-22

D-57392 Schmallenberg

Germany

sales@transfluid.de

www.transfluid.de