WIDIA's Top Ream platform covers the majority of hole finishing needs, with diameters up to 42 mm (1.65 in.) and a range of edge preps and geometries available

Give the locking screw a turn, pop in a new head, and you are up and running, with no concerns over runout or rigidity

"The three keys to hole quality are diametral accuracy, form and position, and surface finish," said a WIDIA spokesperson. "Boring tools are the undisputed king in all of these areas, but they are also one of the slowest methods of hole finishing, and in most cases are limited to 10:1 depth to diameter ratios or less."

"Conventional carbide-tipped reamers produce good hole quality, are substantially faster than boring and able to reach much deeper, but they also have an Achilles heel. The steel shank to which the carbide flutes are brazed has a thermal coefficient three times that of carbide, and is subject to growth during machining operations," said the spokesperson.

"Worse, sharpening of these tools often leads to less than desirable results. The mixture of carbide and steel wreaks havoc on grinding wheels, providing a reground edge that is rarely as good as the original tool. Also, PVD and especially CVD coating of reground tools is problematic, because the temperature inside most coating vessels reaches upwards of 530 °C (986 °F), leading to micro-movement of the brazed carbide flutes."

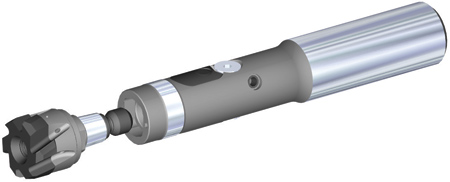

WIDIA Products Group has addressed these problems with its new Top Ream carbide reaming solution. "Instead of four to eight (or more) individually brazed carbide tips, Top Ream uses a single carbide disc and brazed joint, providing a strong connection that is virtually immune to thermal effects during machining operations," said the spokesperson.

"Steel-bodied reamers tend to get banged up on the ends," said WIDIA Manufacturing Engineer Tom Bobos. "The center can get nicked or distorted, preventing an accurate regrind. With carbide, you always have a good center to locate on. The result is a minimum of four "like new" regrinds vs. an average of three questionable ones."

"Overall it is just a better design," said Bobos. "A single piece of carbide is inherently more stable and resistant to vibration. The through-hole style has an 18-degree left hand spiral that does a great job of pushing the chip forward."

WIDIA's WU05PR advanced reaming grade was developed specifically for the demanding tool wear and surface finish requirements encountered in most hole reaming operations. For example, tests performed over a total cut distance 100 feet (30 m) in length showed an ability to consistently maintain surface finishes of 32 µin Ra (0.8 µm) in 4140 steel alloy and 64 µin Ra (1.6 µm) in gray cast iron, three times that of TiAlN-coated tools.

Jerry Hanna, WIDIA Director of Sales Operations, said: "The Top Ream covers hole diameters up to 42 mm (1.65"), with the TRF shank-style starting at 14 mm (0.551"), and the TRM modular tool from 20 mm (0.787") and up. This size range covers the lion's share of requests from our customers. We also offer a wide variety of custom geometries, diameters and edge preps, all available in three weeks or less."

"With reaming, 98 percent of the tools are custom," said Bobost. "We encourage our customers to try standard sizes, but they should also ask us for advice. We have the ability to optimize solutions specifically for any application - if you are machining titanium, there are specific geometries and coatings for that, as with 316 stainless or Inconel. A slight tweak to the hone, or modifying the leading edge a little bit can make a huge difference in productivity and hole quality."

The TRM series' mounting mechanism makes simultaneous contact on the cutting head's face and taper. Twist the locking screw and the reamer head pops out, with no need for head to body orientation. "There is virtually zero runout with the modular design," said Bobos. "Once you have everything dialed in, you just put the head on and tighten it down. There is never a need to re-indicate after a tool change."

For more information contact:

WIDIA Products Group

1600 Technology Way

Latrobe, PA 15650

800-979-4342 / 724-539-5000

na.techsupport@widia.com

www.widia.com