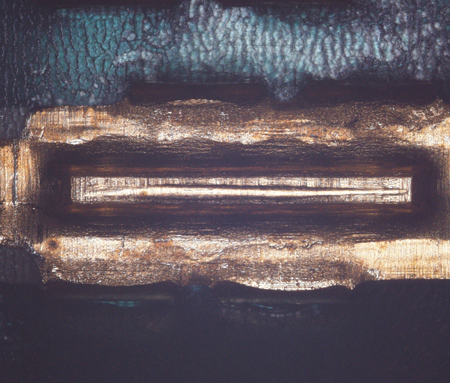

Pressure sensor: During inspection of a crimped terminal with a standard optical microscope, a dent in a crimped terminal is difficult to see due to shadowing. This is caused by the light beam hitting the slope of the crimped terminal. OLYMPUS DSX500 digital microscope, 1x zoom, MIX observation, EFI

With a digital microscope, MIX contrast provides ideal observation conditions by providing enough reflected light to the sensor by using two beams. OLYMPUS DSX500 digital microscope, 1x zoom, MIX observation, EFI

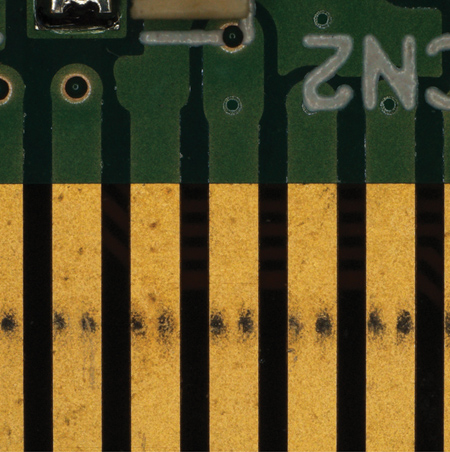

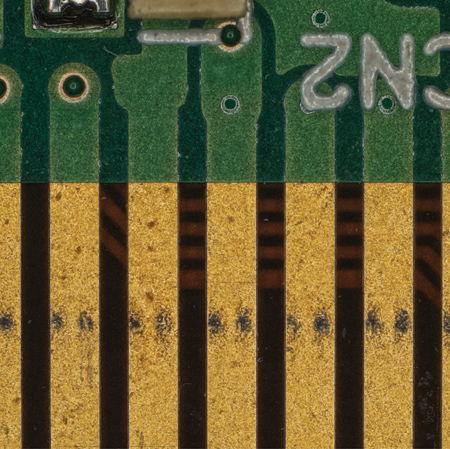

Multilayer circuit board: During observation of inner circuit, when performing this inspection with a traditional microscope, it is often impossible to image the inner pattern of the circuit board because of the highly reflectance pattern on the surface. OLYMPUS DSX100 digital microscope, 2x zoom, upright observation, HDR

Using a digital microscope, a live image can be displayed using HDR observation to combine multiple images with different exposure times. This makes it possible to observe both bright and dark areas at the same time. OLYMPUS DSX100 digital microscope, 2x zoom, upright observation, HDR

"The OLYMPUS DSX500 digital microscope combines the observation power of traditional microscopy with the convenience of today's digital technology, achieving a new level of simplicity with no sacrifice in image quality," said an Olympus Corporation spokesperson. "Even a novice operator can quickly master microscope operation." Digital microscopes are designed for the observation, measurement and analysis of electronic components, circuit boards, construction materials, semiconductors, medical devices, shielding components and more.

With the DSX500, the eyepiece is eliminated, enhancing operator comfort. Onscreen viewing also allows convenient group access and immediate result sharing.

For more information contact:

Olympus America

3500 Corporate Parkway

Center Valley, PA 18034

800-225-8330

www.olympus-ims.com