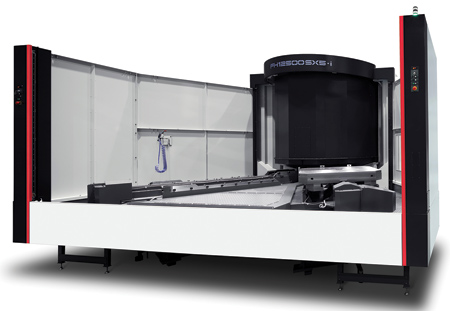

Overall view of the high-capacity JTEKT FH12500 horizontal machining center

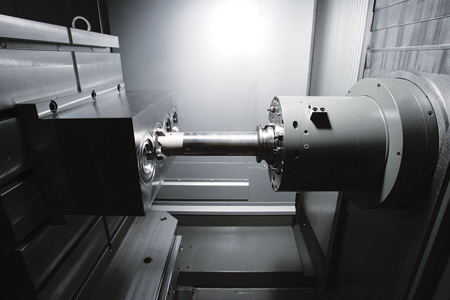

JTEKT FH12500 with spindle in fluid end

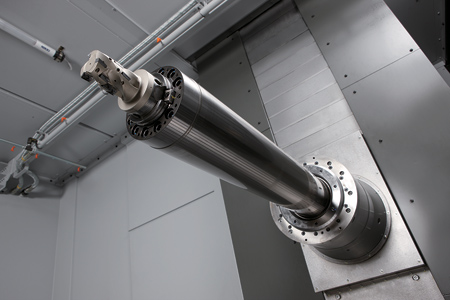

The FH12500 quill spindle option

Quill spindle illustrating quill extension

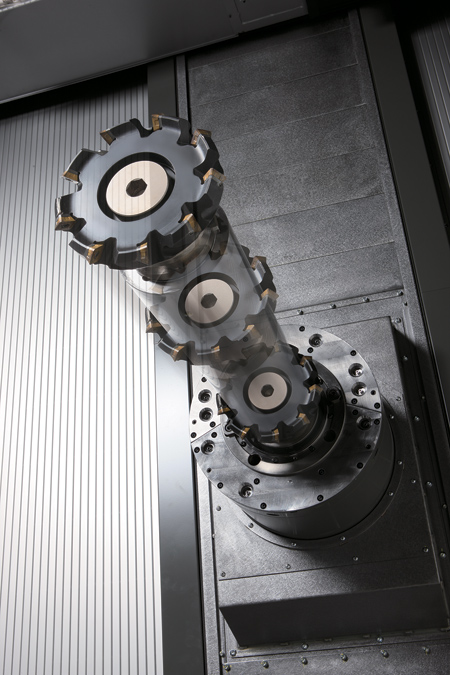

The JTEKT FH12500SX-i is a powerful, high-speed horizontal machining center featuring an upgraded heavy duty 6,000 RPM gear driven spindle with 1,620 ft-lbs. of torque. It offers a pallet capacity of 49.2" x 49.2" (1,250 mm x 1,250 mm) and 11,000 lbs. (5,000 kg). Maximum workpiece swing is 94.5" (o2,400 mm) and the highly capable machine can accommodate workpiece heights to 78.7" (o2,000 mm).

The FH12500 series platform has available spindle options for 8,000 RPM or 15,000 RPM. The 12500SX-i utilizes a cylindrical roller guide design for increased speed as well as dual ballscrew drive on the Y and Z axes for increased rigidity. Axis travels are 94.4" (2,400 mm), 70.8" (1,800 mm), 63" (1,600 mm) for the optional gear driven spindle), and 72.8" (1,850 mm) in Z.

According to a JTEKT spokesperson, "The FH12500 series is the perfect option to reduce cycle times of large components, such as fluid ends, with rapid feedrate of 1,654 IPM and a 3.7 second chip to chip tool change time.

JTEKT and a customer who produces components for the shale oil extraction industry are developing an improved process for fluid end machining on a FH12500. The gear-driven spindle in the JTEKT machine is designed to improve material removal rates with over 1,600 ft-lbs. of torque. Improvement of the MRR will decrease the overall process cycle time, leading to a more competitive machining solution. Data will be collected during this process development period.

"At the completion of the process development project, JTEKT will market this improved solution to identified target prospects in this niche market where our equipment already has a strong foothold and reputation," said the spokesperson.

For more information contact:

John Quick

JTEKT Toyoda Americas Corporation

316 W. University Drive

Arlington Heights, IL 60004

847-253-0340

jquick@jtektmachinery.com

www.jtektmachinery.com