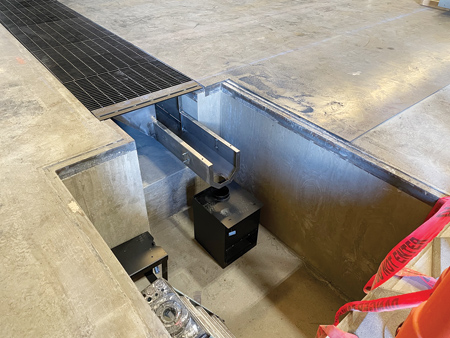

The installation of the auger system that moves reclaimed media back to the machine

Blast room being built.

Titan Abrasive Systems, a manufacturer of surface preparation, surface finishing and sandblasting equipment, has announced the purchase of a new, upgraded blast room by Fab-Tek of Central Mississippi, a provider of metal fabrication and machining solutions.

The blast room will be used primarily to clean and polish the stainless-steel metal conveyor systems they design and manufacture for food processing clients, such as Sanderson Farms and Koch Foods.

To create its high-quality conveyor systems, Fab-Tek purchases flat sheets of stainless steel in large quantities. After running them through the laser cutting, press break, welding and other manufacturing processes, workers use abrasive blasting equipment to produce a smooth, matte finish on the material.

The new blast room measures 15' (W) x 12' (H) x 30' (L). It includes a mechanical recovery system with cross screw (auger); two 6 cu. ft. blast machines; 12,000 CFM cartridge dust collector; and photohelic pressure switch/gauge kit.

The new system replaces an older Titan blast room purchased in 2013. The new room is far bigger and provides much more capacity than the older equipment, which measured 14' (W) x 9' (H) x 22' (L). Plus, the dust collector is twice as powerful, and the cross screw provides a more efficient and less labor-intensive media recovery system, among other upgrades.

"The older room did a terrific job, but we knew it was time to replace it," said Shannon Moore, President of Fab-Tek. "Like any piece of machinery, things started to wear out. Plus, our work had really been picking up, and we needed something bigger to accommodate more workers and more blasting capacity. Based on the performance of the previous room, going back to Titan was an easy decision."

Fab-Tek was primarily using glass beads in its blasting operation and will continue to utilize this medium with the newer equipment, given its excellent performance and the fact that it is highly reclaimable.

According to Moore, the Titan blast room helps Fab-Tek deliver conveyor systems that are not only well-made but are aesthetically pleasing as well. "It really does not matter that it is a conveyor system going into a food processing plant," he noted. "The customers still want it to look good and be proud of it, and so do we."

For more information contact:

Titan Abrasive Systems, LLC

35 Steam Whistle Drive

Ivyland, PA 18974

215-310-5055

sales@titanabrasive.com

www.titanabrasive.com

Fab-Tek of Central Mississippi

19171 Hwy. 51

Hazlehurst, MS 39083

601-892-5017