GENERA has collaborated with Henkel to align its technology, such as the G2/F2-System for digital light processing (DLP), with Loctite's material expertise.

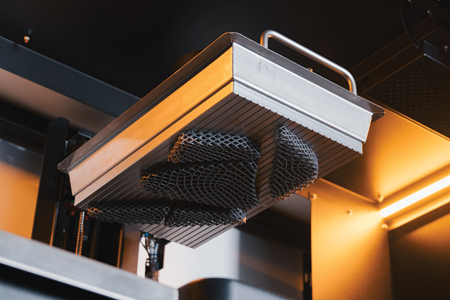

Functional lattice structure required by KTM-E Technologies for seat fabrication printed by GENERA in combination with Loctite 3D 8195.

GENERA joined Henkel's Open Materials Platform with the intention of providing additive manufacturing (AM) solutions at production scale. Combining GENERA's expertise in 3D printing equipment and software and Henkel's expertise in materials, the companies are creating new applications in the automotive and healthcare industries and others.

GENERA's G2/F2-System for digital light processing (DLP) is designed to create a safe, reproducible and comprehensive process for production of 3D models at speed. GENERA's fully integrated process enables a 3D printed part to move from the green state to the finished part using the G2/F2 systems delivering a clean, safe and simple route to finished parts.

Parts printed in the G2 are stored in what is called the shuttle, which allows the safe transfer of parts to the finishing unit F2. An additional feature of this shuttle is a memory chip where all the data of the workflow including the post-processing data of the part is stored. This feature ensures full documentation of the production process harmonizing printing, washing and post-curing. This is a significant feature in industries like automotive and healthcare where quality control and part reliability and reproducibility are critical.

"We are excited to work with GENERA to develop applications that have the potential to impact several sectors," said Sam Bail, Head of Sales for 3D Printing at Henkel. "Our goal with AM is to drive production at scale, and we believe that by collaborating with the ideal ecosystem partner, the Loctite 3D printing materials will become a significant enabler."

A recent example of where GENERA's fully integrated process and the Loctite 3D elastomeric photopolymer range solved a design challenge was in the fabrication of seat parts. KTM-E Technologies approached GENERA to design and manufacture prototype parts with elastic materials to create seats containing a functional lattice structure. Many industrial 3D printers could not produce the prototype parts with the quality and standards that are required for further series production. The GENERA printer stood out, in combination with Loctite 3D 8195. "AM is and will be a key technology in manufacturing, not only for prototype parts but also for serial production," said Florian Fischer, Project Lead for Additive Manufacturing at KTM E-Technologies. "GENERA's 3D printing system helps us to find better solutions for the mobility of the future."

Moving forward, Henkel and GENERA plan to expand the portfolio of materials that can be used on the Genera printer. "We are very happy to expand our material portfolio to greater than 10 Loctite 3D printing resins, serving several market applications, which have been validated on our G2/F2 System," said Dr. Klaus-Peter Stadlmann, CEO and founder of GENERA Printer GmbH.

For more information contact:

Henkel Corporation

One Henkel Way

Rocky Hill, CT 06067

860-571-5100

www.henkel-northamerica.com

GENERA

www.genera3d.com