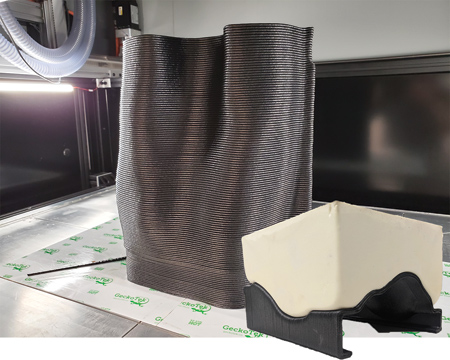

A shop that needed to create its own rigid foam casting molds found that 3D printing the mold in-house significantly reduced lead time and process waste, allowing for a more efficient process.

The Tradesman Series P3-44 has a floorspace of 73" x 138" x 110" and a work envelope of 36" x 48" x 48".

"The manufacturing industry has been thrown into uncertain times of labor shortages, supply chain issues and logistics nightmares," said a JuggerBot 3D spokesperson. "As a result, more and more shops have been lowering costs and lead times by producing their own tooling, replacement parts, shipping braces and more. JuggerBot 3D has been helping CNC machine shops do just that. Our large format Tradesman Series has proven to withstand the same warehouse conditions as existing CNC machines, making them the perfect fit for machine shop owners."

Application possibilities for JuggerBot 3D's filament or pellet printers extend into the needs of shops across multiple industries. Recent customer applications include prototypes, quality tools, production patterns and molds. "These shops have seen significant reduction in machine down time, logistics costs and lead times-especially in remote areas," said the spokesperson.

JuggerBot 3D's printers offer fast printing speeds and optimal material control through their filament and pellet extrusion technologies. A patented interdependent drive system on the F3-32 filament printer uses push and pull forces to control material and enables operators to select from a wide variety of performance materials.

"The P3-44 pellet extrusion machine enables faster printing speeds with production-ready materials, addressing some of the biggest challenges facing industrial 3D printing. JuggerBot's pellet extrusion technology came from a partnership with Oak Ridge National Laboratory and increases throughput up to 200x times faster than other 3D printers," said the spokesperson.

Both printers are material-agnostic and designed to process performance thermoplastics for demanding applications. The self-contained architecture allows either JuggerBot 3D printer to share the same shop floor with a company's CNC machines. "Anchored by an environmentally controlled build chamber and robust process controls, failed prints and quality issues commonly plagued by lesser units are eliminated," said the spokesperson.

Large build volumes enable manufacturers to print a wider range of product designs up to 3' x 4' x 4' in size. The work envelope of JuggerBot 3D's printers accommodate batch order printing to increase production.

JuggerBot 3D's expertise extends into training and service from certified technicians and engineers. Coupled with remote monitoring software, our manufacturing partners get the most value out of their tool sooner rather than later. In Ohio and Pennsylvania, JuggerBot 3D has partnered with expert machine tool dealers, JBM Technologies, to bring customers their experienced service and engineering capabilities.

For more information contact:

JuggerBot 3D

241 W Federal Street

Youngstown, OH 44503

330-406-6900

www.juggerbot3d.com

NORTHEAST

PA

JBM Technologies

76 Vincent Circle

Ivyland, PA 18974

877-526-6224

www.jbmtechnologies.com

MIDWEST

OH

JBM Technologies

76 Vincent Circle

Ivyland, PA 18974

877-526-6224

www.jbmtechnologies.com