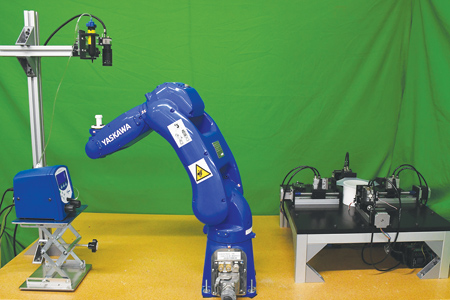

The Yaskawa GP8 robot equipped with robust vision capability facilitates high-speed 3D mesostructure assembly at USC's Center for Advanced Manufacturing.

The Yaskawa GP12 robot with a Miller Auto-Continuum 350 welding power supply brings high-performance capability to USC's CAM wire arc AM process for building conformal steel structures.

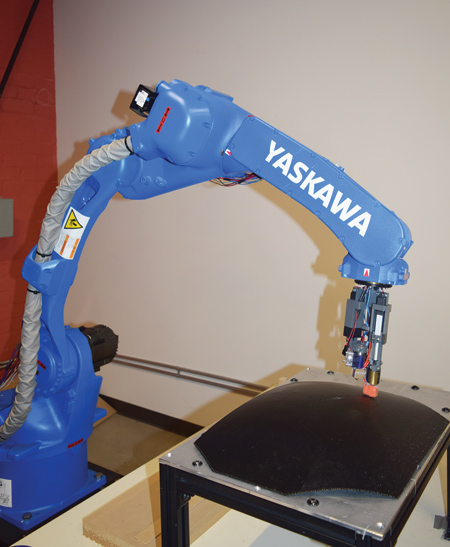

The Yaskawa GP12 robot with a fused deposition modeling (FDM) extruder brings high-performance capability to USC's Center for Advanced Manufacturing 3D printing process.

With stark predictions that 4.6 million manufacturing jobs will need to be filled in the United States over the next decade, with the prospect of 2.4 million of those going unfilled due to lack of training, it is more important than ever to build an adaptive workforce skilled in Industry 4.0 technologies, including next-generation robots.

For the Center for Advanced Manufacturing (CAM)-an interdisciplinary in the University of Southern California (USC) Viterbi School of Engineering-this means transitioning educational research into practice. Through investigation and application, USC students become empowered innovators that provide the Southern California community and participating partners with advanced manufacturing capabilities.

Housed in a state-of-the-art 10,000 sq. ft. facility, CAM features the latest technologies for polymer processing, CNC machining, additive manufacturing (AM) and robotic automation. Not only does this strict focus on STEM technology cultivate employees ready to work on day one after graduation, but also, it maintains a high level of enthusiasm for the primary skill sets needed to fulfill the industrial tasks of the future.

As more students realize the employment opportunities available to them, the need for hands-on robotics training grows. "We work with a number of aerospace and defense companies-all of them view robotics and autonomous systems as important technologies," said Satyandra K. Gupta, Ph.D., the Center for Advanced Manufacturing Director. "By providing access to industrial robots, we can provide our students meaningful, yet practical, learning experiences that are useful beyond the classroom."

A part of the Advanced Robotics for Manufacturing (ARM) Institute consortium (www.arminstitute.org), CAM works with other member organizations and manufacturers to develop innovative solutions that strengthen the future of U.S. manufacturing. "Collaborating with industry experts from leading companies like Yaskawa Motoman is especially helpful in gaining access to the most suitable technologies for high-priority training lab projects," said Gupta.

The CAM facility currently has five Yaskawa robots that are instrumental to student training for a variety of applications, including conformal 3D printing, mesoscale AM, wire arc AM, flexible material manipulation and sorting. Next-generation Yaskawa robots, such as the GP12, GP8 and AR2010, are Robot Operating System (ROS) compatible, allowing CAM students to harness a blend of advanced algorithms, software, drivers, functions and more through the open source repository supported by Open Robotics at ros.org.

Collaborating with Yaskawa provides convenient access to robots, as well as valuable advice from experts like Eric Brooks, Senior Director of Operations for Yaskawa Motoman's Western Regional Center in Irvine, CA. "This support truly enhances the educational experience for our students," said Gupta. "It fosters the industrial knowledge needed to perform the hands-on skills required by many employers today."

For more information contact:

Yaskawa America, Inc.

Motoman Robotics Division

100 Automation Way

Miamisburg, OH 45342

937-847-6200

www.motoman.com

USC Center for Advanced Manufacturing

1115 W 25th Street

Los Angeles, CA 90007

sites.usc.edu