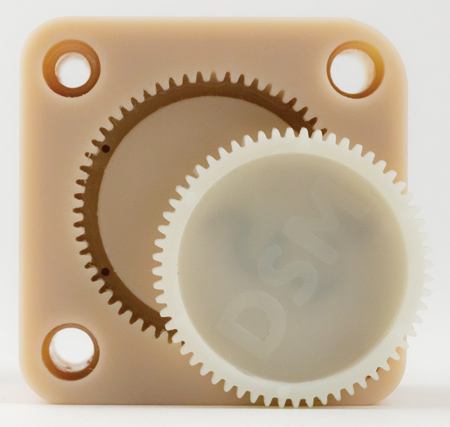

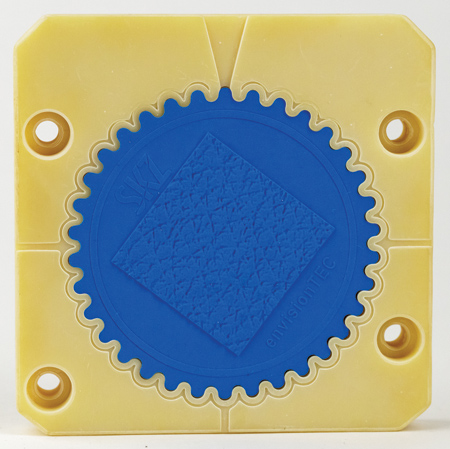

A tool used for injection molding glass-filled nylon gears is 3D printed on EnvisionTEC's Perfactory P4K series printer using the e-PerFORM resin

3D printed tool for injection molding

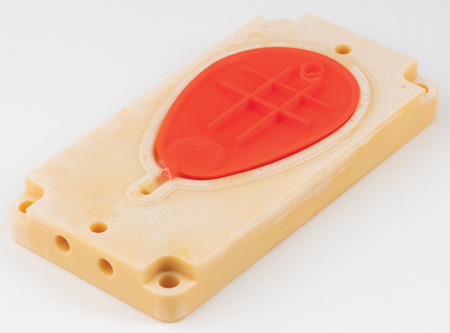

Injection molded part using 3D printed tool

EnvisionTEC and Covestro have announced their collaboration on material+printer solutions to accelerate adoption of industrial 3D printing. Together, the two companies aim to lower the entry barriers for companies looking to adopt 3D printing for producing molds for low volumes or parts with detailed features faster and more economically.

"The combination of Covestro material expertise and EnvisionTEC printer technology resulted in a complete industrial manufacturing solution for 3D printing injection mold tooling," said a spokesperson. "Until now, no solution was available that met the stringent industry-required properties in terms of dimensional stability and minimal warpage. The patented material formulation from e-PerFORM, optimized for EnvisionTEC's equipment, brings the benefits of Somos PerFORM to a faster and more economical printer technology."

To bring customers a workable and demonstrated material+printer solution, EnvisionTEC and Covestro optimized print parameters and verified Covestro's DLP resin e-PerFORM on EnvisionTEC's Perfactory P4K series printer. EnvisionTEC further tested e-PerFORM resin with key molding institutes to validate the material's performance. "Completed mold trials demonstrate that e-PerFORM resin, with high stiffness and high temperature performance, behaves similarly to stereolithography resin Somos PerFORM for injection molding tooling," said the spokesperson.

Al Siblani, EnvisionTEC CEO, said: "The combination of our P4K printer and Covestro e-PerFORM optimized for our printers enables fast, cost-effective production of injection molding tooling. Our collaboration has resulted in a new and much-needed solution."

Hugo da Silva, Head of Additive Manufacturing at Covestro, said: "By working closely with our partner EnvisionTEC, we developed a material that meets critical needs voiced in the market: improved dimensional stability and minimal warpage for optimal functionality. The validation and proven solution with their P4K printers will help accelerate the adoption of additive manufacturing of injection mold tooling."

For more information contact:

EnvisionTEC, Inc.

15162 S Commerce Drive

Dearborn, MI 48120

313-436-4300

www.envisiontec.com

Covestro

addigy.covestro.com