Röhm CoAE with center and driver disc, morse taper and draw-off nut, as well as interchangeable parts including two different centers, a driver disc with gearing and a driver disc with hard metal inserts.

CoAE in the assortment box with centers and driver discs

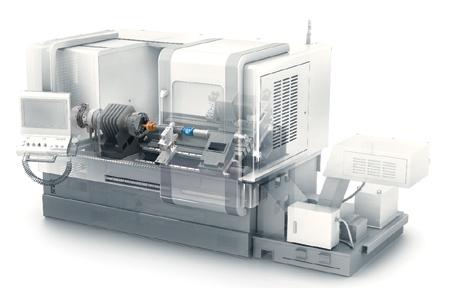

Application principle of the CoAE face driver on a CNC turning machine with counter-clamping by a center and central support with a steady rest

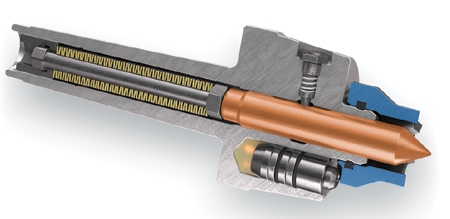

Cross-section of CoAE (with morse taper) with exchangeable center and driver disc

RÖHM's latest CoAE face driver for turning and milling offers increased power and accuracy. The CoAE's assortment of exchangeable driver discs and centers enable the machining of very different workpiece geometries with just one basic set-up. The driver discs are mounted on the unit without any radial play in order to enable high accuracy, even when the rotational direction is reversed during machining. Moreover, the hydraulic drive support compensates for face perpendicularity errors and helps ensure a precise connection of the face driving device and the workpiece.

"Experienced lathe operators recommend turning between centers for machining a turned part over the entire length of the workpiece. However, when you need to apply high cutting force, then just one center is not enough to support the transfer of torque," said a company spokesperson. "This is the scenario that main-spindle face drivers like the CoAE are made for. The driving disc teeth press into the driven face of the workpiece, so torque can be adequately transferred. The CoAE face driver also utilizes a center to adequately locate the workpiece on the centerline and maintain concentricity. Our newest face driver is ideal when you cannot reclamp a shaft and need to machine it to the end, or when the clamping marks are not allowed on the workpiece O.D. surface." Face drivers like the CoAE are typically used in the manufacture of drive shafts, gear shafts, camshafts, rotor shafts and crankshafts.

The new CoAE is a next-generation face driver that combines the assets of two RÖHM solutions, the CoA and CoE. From the CoA, which is mainly used for turning, the CoAE incorporates hydraulic compensation of the driver discs. The CoAE's zero-play feature was inspired by the CoE, a face driver optimized for mill-turn machining.

The new CoAE allows users to machine workpieces up to 350 kg (772 lbs.). The CoAE can be axially loaded by up to 8 kN to transfer sufficient torque for workpieces of this size. The unit's concentricity is a precise 0.015 mm.

The driver discs are exchangeable and cover a diameter range from 8 mm up to 80 mm. For particularly hard workpieces, the CoAE utilizes driver discs with exchangeable hard metal inserts. RÖHM provides separate driver discs for counter-clockwise and clockwise rotation, as well as bi-directional driver discs that support both counter-clockwise and clockwise rotation. These discs enable an optimal connection to the workpiece and allow the machine to apply high cutting power.

The CoAE supports multiple spindle connections. It comes with a cylinder shank (usually for clamping in a chuck), a Morse taper (optionally with draw-off nut) and mounting flanges with a short taper.

RÖHM's CoK-AE face-driver variant is designed for force-actuated machine tools. The CoK-AE is suitable for high workpiece weights (up to 700 lbs.) that require a suitable axial force for torque introduction.

For more information contact:

RÖHM Products of America

2500 Northlake Drive

Suwanee, GA 30024

770-963-8440

sales@rohm-products.com

www.rohm-products.com