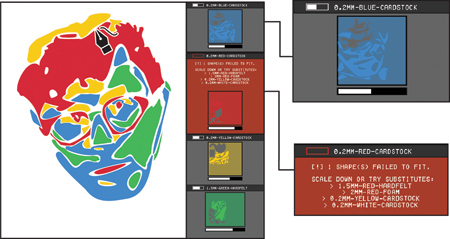

Fabricaide provides live feedback on laser-cut designs, such as warnings about whether the materials will fit on the sheets to be cut.

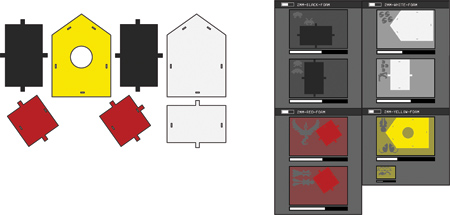

Fabricaide provides information on the different materials being used and how much of each is left.

Fabricaide's packing algorithm can arrange parts onto sheets in an optimally efficient way.

Researchers from MIT's Computer Science and Artificial Intelligence Lab (CSAIL) have created a new tool for laser-cutting called Fabricaide. The solution provides live feedback on how different parts of a design should be placed onto sheets, and can even analyze exactly how much material is used.

"By giving feedback on the feasibility of a design as it is being created, Fabricaide allows users to better plan their designs in the context of available materials," said PhD student Ticha Sethapakdi, who led the development of the system alongside MIT professor Stefanie Mueller, undergraduate Adrian Reginald Chua Sy and Carnegie Mellon PhD student Daniel Anderson.

Fabricaide has a workflow that the team says significantly shortens the feedback loop between design and fabrication. The tool keeps an archive of what the user has done, tracking how much of each material they have left. It also allows the user to assign multiple materials to different parts of the design to be cut, which simplifies the process so that it is less of a headache for multi-material designs.

Another important element of Fabricaide is a custom 2D packing algorithm that can arrange parts onto sheets in an optimally efficient way in real time. The team showed that their algorithm was faster than existing open-source tools while producing comparable quality. The algorithm can also be turned off if the user already knows how they want to arrange the materials.

"A lot of these materials are very scarce resources, so a problem that often comes up is that a designer does not realize that they have run out of a material until after they have already cut the design," said Sethapakdi. "With Fabricaide they would be able to know earlier so that they can proactively determine how to best allocate materials."

As the user creates a design, the tool optimizes the placement of parts onto existing sheets and provides warnings if there is insufficient material, with suggestions for material substitutes (i.e., using 1 mm-thick yellow acrylic instead of 1 mm red acrylic). Fabricaide acts as an interface that integrates with existing design tools, and is compatible with both 2D and 3D CAD software like AutoCAD, SolidWorks and even Adobe Illustrator.

In the future the team hopes to incorporate more sophisticated properties of materials, like how strong or flexible they need to be. The team says that they could envision Fabricaide being used in shared makerspaces as a way to reduce waste. A user might see that, say, 10 people are trying to use a particular material, and can then switch to a different material for their design in order to conserve resources.

The project was supported in part by the National Science Foundation.

For more information contact:

MIT CSAIL

32 Vassar Street, Office 273

Cambridge, MA 02139

617-324-9135

csail.mit.edu