Medical part with gundrill

The UNE6-2i is a complete system that offers automatable, on-demand deep hole drilling processes.

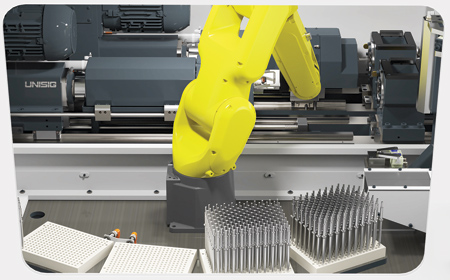

UNE6-2i in-machine automation: after the front spindle drills the first hole, a robot takes it out of the spindle, puts the hole onto the second spindle and loads another fresh blank into the first spindle.

Medically speaking, cutting people open is dangerous. Today, physicians get around this problem by using modern surgical instruments to perform minimally invasive procedures, which can turn major operations into simple outpatient appointments.

"In order to accomplish these feats of surgical science, manufacturers in the medical industry have to drill small-diameter holes through the entire length of slightly larger instruments," said a UNISIG spokesperson. "Thin part walls, intricate features, high surface quality and concentricity requirements, and extreme depth-to-diameter (D:d) ratios make these parts challenging to produce efficiently-especially without the one-piece-flow processes that advanced deep hole drilling systems can enable with in-machine automation."

A typical laparoscopic surgical instrument, for example, is designed to direct tools, cameras and other devices into the body through the instrument using a guide wire. As a result, highly precise hole concentricity is required to ensure smooth, reliable and accurate performance during procedures. "Because these are long, thin tools, the holes through their centers often have D:d ratios well above 100:1, a depth that can challenge even dedicated deep hole drilling equipment, much less the Swiss-style machines favored by many medical manufacturers," said the spokesperson.

The spokesperson continued, "Of course, it is very hard to find a better solution for cutting features on the outer diameter of surgical instruments than a Swiss-style machine. With the support of a guide bushing, these machines can cut numerous intricate features into small-diameter bar stock, performing multiple secondary operations like drilling cross holes or milling slots in parallel with the turning operations. With a bar feeder and parts catcher, a Swiss-style machine will out-produce any other solution when it comes to medical parts-until it comes to deep holes.

"Given their reliance on guide bushings for stability, Swiss-style machines' spindles often lack the rigidity or speed needed for effective deep hole drilling, especially in tough medical-grade materials like titanium and stainless steel. Without high-pressure, through-tool coolant, they also have trouble evacuating chips. To compensate, Swiss-style machines have to slow way down to reach the necessary hole concentricity and tolerances, and the process will still often lead to broken drills and scrapped parts."

Manufacturers often try to address this by designing tools with larger hole diameters at the surgeon's end of the instrument. The concentricity requirements of these larger diameters are not as tight, and are thus a bit more forgiving when drilling. "However, this 'easier' hole can, in turn, produce even more challenges," said the spokesperson. To drill a second hole at the opposite end of the part, it must be moved to an often less-capable sub-spindle, slowing production down even further."

With these challenges, it is no surprise that many manufacturers try to skip the deep hole drilling process altogether by farming out the work, but going to outside suppliers can bring its own problems. "Pre-drilled blanks might solve the deep hole drilling problem, but they have to be fed into the machine one by one, defeating the whole purpose of using automation-ready Swiss-style machines," said the spokesperson. "Meanwhile, cannulated bar stock allows shops to continue using their bar feeders, but it is very expensive-and the hole quality and O.D./I.D. concentricity rarely meet the needs of medical manufacturers anyway."

To overcome these challenges, medical manufacturers are turning to dedicated deep hole drilling equipment to finish instruments started on the Swiss-style machines. "With an experienced gundrill operator, careful set-up and a bit of finesse, the hole quality can be excellent, and it allows the Swiss-style machines to remain fully automated," said the spokesperson. The only remaining problem is the space between the two machines, since the part movement introduces significant risks when the accuracy requirements are so high. Additionally, if the part has to be flipped to drill a stepped bore, it introduces more set-up operations and more risk of human error.

"What medical manufacturers need is a truly end-to-end automated process that allows for an efficient single-piece workflow for surgical instruments," said the spokesperson. "Some deep hole drilling OEMs, such as UNISIG, have engineered all the technology required to meet this goal. The result is the UNE6-2i, a complete system that offers easily automatable, on-demand deep hole drilling processes for the most demanding surgical instrument applications."

The spokesperson continued, "As a twin-spindle machine with two independent drilling axes, the UNE6-2i inherently has the capabilities manufacturers expect from a high-performance deep hole drilling machine. Counter-rotation, specialized workholding and superior alignment and precision allow shops to confidently hold concentricity tolerances and minimize mismatches, even at the extreme D:d ratios common in the medical industry." In addition, the UNISIG Smart Control Interface simplifies operation, while an innovative flow-based coolant system automatically reacts to pressure changes for effective chip evacuation and high process security.

"What allows the UNE6-2i to truly shine as a part of the surgical instrument production process, however, is the in-machine automation," said the spokesperson. After the front spindle drills the first hole, a robot takes it out of the spindle, puts the hole onto the second spindle and loads another fresh blank into the first spindle. The robot's repeatability helps ensure high hole quality-and the only human labor required for the process is loading bar stock into the Swiss-style machines, preparing the blanks for the UNE6-2i's robot and sending the finished parts on for post-processing.

The UNE6-2i's capabilities also give manufacturers significant production flexibility. Two holes with two different diameters could be simultaneously drilled in a single part, or two parts could be in-process simultaneously to allow operators or robots to load and unload the machine without stopping. Alternately, this twin-spindle configuration can be used to drill halfway through a part from one end with the first spindle and allow the second spindle to finish the hole from the opposite end.

"However, many shops are only convinced to invest in the technology after they see the high part quality that is achieved in the extremely fast production cycle," said the spokesperson. "Instead of worrying over runout when moving parts from a Swiss machine to a gundrill-or over-paying for cannulated or pre-drilled hardstock that fails to meet the quality requirements for medical parts-in-house processing via advanced deep hole drilling systems like the UNE6-2i allows manufacturers to achieve far greater consistency, concentricity and quality with their medical parts."

Some manufacturers may be concerned about lacking experience with deep hole drilling systems when it comes to process development. For highly precise medical parts, establishing the ideal speeds and feeds is critical to meet tight tolerances. "The dedicated application, technical and training support available from deep hole drilling OEMs such as UNISIG can be invaluable to these shops," said the spokesperson.

In many cases, the technical and engineering teams at OEMs like UNISIG can work directly with manufacturers to develop complete turn-key solutions for deep hole drilling applications. This level of process collaboration can include highly specific application support, such as solutions for handling shorter-than-usual drilling operations or clamping systems that support parts via the outside diameter to further increase repeatability. Systems such as the UNISIG UNE6-2i gundrilling machine can even provide all this in a footprint that easily fits into the average medical shop environment.

"More shops than ever are changing the way they approach medical manufacturing with the power of high-performance deep hole drilling machines," concluded the spokesperson. "Much like the minimally invasive procedures enabled by these challenging parts, these machines reduce risks and improve outcomes when producing thin-walled, small-diameter holes in medical instruments. Today it is easier than ever to integrate these machines into a shop's processes, allowing manufacturers to realize all the benefits of deep hole drilling in-house."

For more information contact:

UNISIG

N58W14630 Shawn Circle

Menomonee Falls, WI 53051

262-252-3802

sales@unisig.com

www.unisig.com