"Many agricultural machinery manufacturers use Heckert machines to machine axes, gearbox housing, engine blocks and hydraulic systems and more, since machining these types of components requires high-performance machining centers that feature a rigid design and provide precise and reliable manufacturing processes," said a Starrag spokesperson.

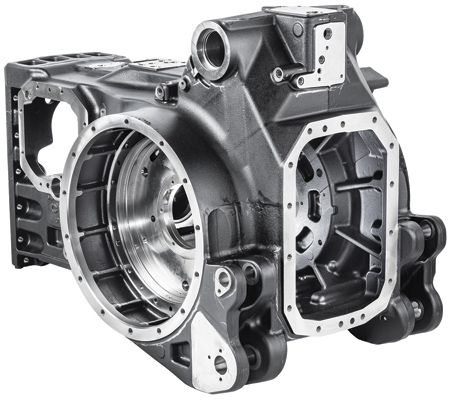

Axis drive housings, components used in agricultural machinery, are primarily made of steel and cast iron and, in many cases, are large, heavy and challenging in terms of their contours.

Upon request, Starrag can equip its Heckert machines with an NC quill that can extend up to 20" (500 mm) in the Z-direction on compact models.

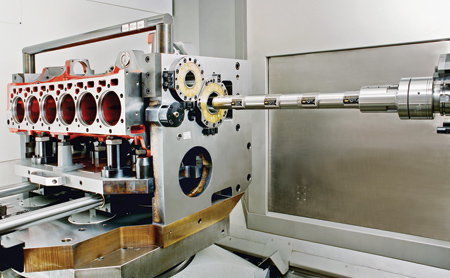

Long boring bars are used to produce crankshaft and camshaft bores on the straight-four or straight-six engines commonly used in agricultural machinery. For this type of application, Starrag offers the HEC 800 machining center with an optional Z-path of 98" (2,500 mm).

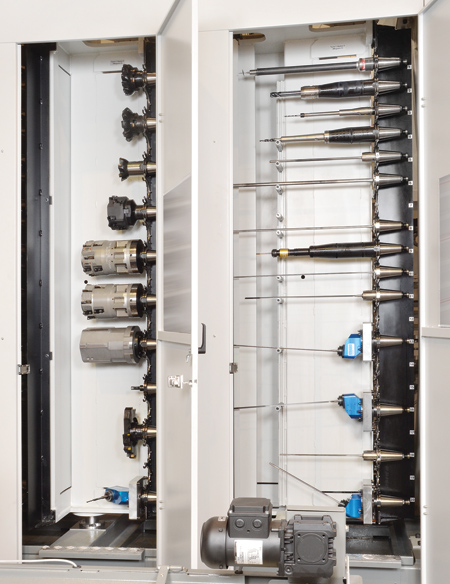

The tool magazines available feature a capacity of up to 450 pieces and, depending on the design and machine, are able to automatically change tools up to 59" (1,400 mm) in length as well as bridge bars with a width of up to 37" (950 mm).

Starrag offers tailor-made solutions for steel and cast iron workpieces used in the agriculture manufacturing industry.

"According to a Global Markets Insights report, there is a growing demand in the agriculture market industry due to the rise in global population. As a result, the $150B agriculture equipment market size is projected to grow over 6% annually through 2026," said a Starrag spokesperson. "More than six million units were shipped globally in 2019 with the market growth attributed to a growing demand of packaged, high energy and processed foods, as well as meats. Not surprisingly, according to the report, high-capacity agriculture machinery is in greater demand."

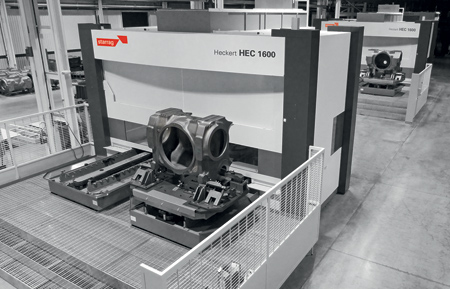

Heckert machining centers from Starrag include 4- and 5-axis machine designs and flexible configuration options that range from a single machine to an automated production line, offering enhanced productivity even in the case of low and medium-quantity production. The solutions are suitable for machining engines, gearbox housings, axes and other heavy, bulky components.

"For agricultural vehicles, the lightweight solutions commonly used in passenger cars are hardly ever appropriate. What is needed instead is robust mechanical engineering," said Kai Bohle, Starrag Sales Manager for the Transportation and Industrial segment based in Chemnitz, Germany. "Components used are primarily made of steel and cast iron and are in many cases large, heavy and challenging in terms of their contours."

When discussing vehicle manufacturing, Bohle said many people think of passenger car and truck production, which involves manufacturing tens of millions of units per year. "But construction vehicles and agricultural vehicles are no less interesting-and crisis-proof to boot," he said. "They are manufactured in significantly lower quantities and are much more specialized in their design. Consequently, many components differ from their counterparts on the mass market of the automotive industry in terms of their dimensions, materials, component mass, batch sizes and number of variants."

Machining components such as axes, gearbox housings, engine blocks, cylinder heads and hydraulic component systems require high-performance machining centers with a rigid design that helps ensure precise and reliable manufacturing processes. "These properties are part of the DNA of the horizontal Heckert HEC machining centers," said Bohle. "Because of this, many manufacturers of agricultural machinery use compact Starrag Heckert centers with pallet sizes 16 in. to 32 in. (400 mm to 800 mm). There is also a high demand in the agricultural sector for the large machines from the Heckert Large Athletic series. These machines feature pallet sizes starting at 39 in. x 32 in. (1,000 mm x 800 mm) and can be used for large-volume and heavy components."

The Perfect Conditions for Cast Machining

"All of these machines feature rigid, thermo-symmetrically designed major components and digital AC feed drives, as well as elaborate profile rail guides and ball screw spindles in all linear axes," said the spokesperson. "Supplemented by a robust and powerful high-torque spindle, the machines offer long-lasting high precision and reliable processes, even in the case of materials that are difficult to machine. The free chip fall also plays an important role, especially when machining cast components. These components often have large material allowances that result in a large amount of chips."

A fundamental advantage of the Heckert HEC centers, according to Bohle, is that the axis traverse paths are relatively large in relation to the pallet size. "If these are a crucial decision-making factor in the buying process, the customer may, in certain circumstances, be able to opt for a machine that is a size smaller and thus cut costs," he said.

Starrag is able to meet the requirements of agricultural engineering with customer-specific solutions based on its Heckert machining centers, according to Torsten Leistner, team leader for Project Engineering at the Product Range Heckert. "Together with the customer, we develop the machining technology and design the fixtures and automation systems that best suit the batch size," said Leistner, whose team includes experts in application technology, automation, layout creation and special designs.

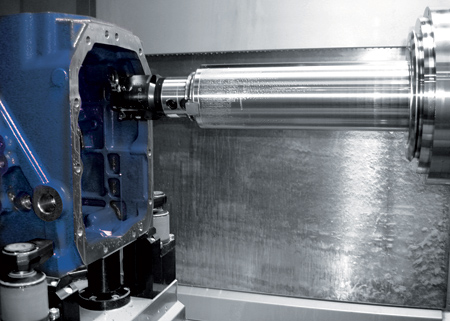

Quills for Axis Drive Machining

A standard process in agricultural machinery manufacturing is the machining of half-axes and axes drives. Starrag can equip its Heckert machines with an NC quill to machine bearing seats or other molded elements in the interior space. This quill can extend up to 20" (500 mm) in the Z-direction on compact models. It measures 5" (125 mm) in diameter and offers a maximum speed of 4,000 RPM. For the larger machining centers with a pallet size starting from 39" (1,000 mm), there is an additional quill measuring 6" (150 mm) in diameter and with a traverse path of 30" (760 mm).

"Using such a quill is a cost-effective alternative to using expensive, vibration-damped standard tools that require extensions," said the spokesperson. The improved length-to-diameter ratio also leads to increased process stability.

"The NC quill forms a unique selling point for the compact machining centers and can be used in many versatile ways in agricultural engineering applications," said Leistner. "This is because the quill can also be used for machining gearbox housings and half axes with long axis funnels that would otherwise require long tools that are consequently susceptible to vibrations."

Long tools still remain indispensable for certain applications, such as for producing crankshaft and camshaft bores in the straight-four or straight-six engines commonly used in agricultural machinery. To ensure the longevity of such an engine, the bores must be made with high precision in one pass.

Increased Productivity with the 5-Axis Design

The Heckert HEC machining centers with a 5-axis design are designed for a wide variety of machining applications. The HEC 500 to HEC 800 compact machining centers are equipped with a rotary swivel table; the large centers have a swivel head as a fifth axis. This reduces the number of clamping positions, resulting in shorter non-productive times and thus greater productivity.

The advantages of the 5-axis Heckert centers can also be leveraged when machining the bulky swing axes of agricultural equipment. For example, an axis clamped above cheek height can be machined on both front faces using a Heckert HEC 800 X5 machine without the need for reclamping. In addition, the attachment points along the longitudinal axis can be precisely positioned and fitted by adjusting the fifth axis. The benefit is greater accuracy and shorter tool changing times.

An additional core capability of the 5-axis Heckert machines is the ability to carry out the complete machining of the planetary gear carriers installed in the gearboxes and sometimes also in the axes of agricultural machinery. It helps ensure precise positioning, allowing the required shape and position tolerances for the planetary gear bores to be complied with. The integrated turning function eliminates the need to transfer the workpiece to a lathe. Additionally, the ability to carry out direct toothing in one clamping operation increases the profitability of the machining process.

For more information contact:

Starrag USA Inc.

Skyport Business Park

2379 Progress Drive

Hebron, KY 41048

859-534-5201

ussales@starrag.com

www.starrag.com