CBN Grooving Inserts Improve Tool Life

May 1, 2021

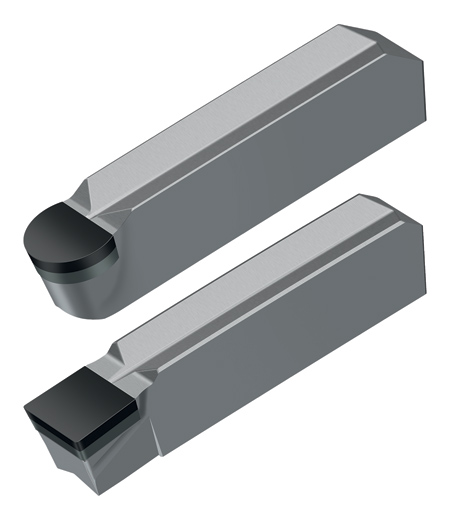

Walter CBN grooving inserts

WBH20 and WBS10, part of the latest generation of CBN insert grades from Walter, are designed to provide optimum surface quality, high process reliability and extended tool life in grooving operations on the toughest materials. WBH20 is a grade suited for ISO-H Group of material, such as for hard turning applications. WBS10 is suited for ISO-S materials, specifically nickel-based (such as Inconel), iron-based (such as Udimet) or cobalt-based (such as Hayens).

WBH20, with 50% CBN content and optimized grain structure, is wear-resistant at medium cutting speed. With a T-land of 0.008" x 20°, it was developed to enable components of hard ISO H materials up to 65 HRC to be grooved efficiently and with low wear during either smooth or interrupted cut. Typical areas of application include the automotive and agricultural equipment industry as well as general machining and energy.

WBS10 grade was developed for aerospace materials, specifically super alloys from ISO-S materials group. "Among other tasks, it excels in grooving materials such as Inconel on engine components, and in the oil, gas and energy industries as well as general mechanical engineering," said a company spokesperson.

With its light hone and medium CBN content (65%), this grade is suited for higher cutting speeds (800-980 SFM) in super alloys such as Inconel-718. Increased production capacity from the same machine to free up machine time, and highly cost-effective operation due to low unit costs are some additional benefits of this grade.

For more information contact:

Walter USA LLC

N22 W23977 RidgeView Pkwy West

Suite 100

Waukesha, WI 53188

800-945-5554

www.walter-tools.com/us

< back