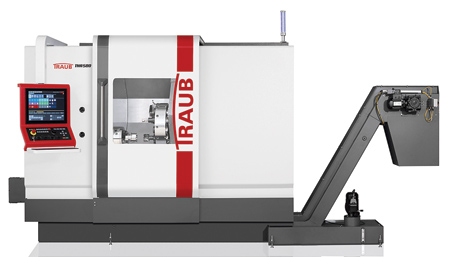

TNA500 CNC universal turning machine

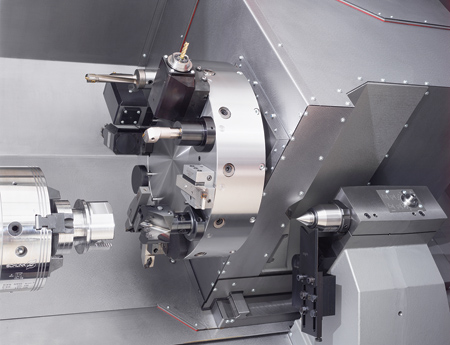

Counter spindle with a VDI40 radial turret

"Powerful and precise machining of customized flange and shaft parts from a batch size of one is the key feature of the current INDEX CNC universal turning machine series," said a company spokesperson. "This includes the INDEX B400 and B500 models, as well as the TRAUB TNA400 and-the newest member of the family-the TRAUB TNA500. Compared to the TNA 400, it is primarily distinguished by larger, more powerful spindles. Offering an outstanding price/performance ratio, it is a promising general machine."

The TRAUB TNA500 universal turning machine is equipped with an A11 main spindle with 102 mm spindle clearance, 400 mm chuck diameter and 750 mm turning length. The belt-driven 37.5 kW spindle provides a maximum speed of 3,150 RPM and a torque of up to 1,020 Nm-around 40% more power than the TNA400.

The four universal turning machines have a lot in common: they use the same machine bed, cover, inner cover and slide systems. A fundamental difference between the INDEX and TRAUB machines can be found in their installed control technology. While the INDEX B400 and B500 are equipped with the latest Siemens Sinumerik 840D sl, the TRAUB TNA400 and TNA500 incorporate the TRAUB TX8i-s V8 controller based on Mitsubishi controls.

Counter Spindle for Precise Rear-End Machining

To support long workpieces, the TRAUB TNA500, like the TNA400, offers the possibility of using a tailstock mounted on generously dimensioned roller guides. As an option, the machine is also available with an A8 counter spindle, which allows the operator to use the parts machined on the main spindle for rear-end machining with precise positioning and concentricity.

In this counter spindle version, the TNA500 is equipped with a VDI40 radial turret. Its 12 stations use the patented INDEX W-serration. Their profile helps ensure that the basic holders on the tool turret can be aligned quickly and easily. The repeatability of the system achieves results in the micron range.

Instead of the radial turret, an alternative option is the installation of a VDI40 disk-type turret. Its main strong points come to the fore, in particular when using large solid drills or boring bars, since this design principle means that forces are transmitted vertically into the turret.

High Efficiency Through Automation

The TRAUB TNA500 universal turning machine, like its platform siblings, is not only suitable for small batch production. Options are also available for machining medium-size batches. For example, there is an optional bar package for use in attaching a bar loader, which consists of the required hollow clamping cylinder and a remnant/workpiece removal unit. This handling device can accommodate workpieces up to a main and counter spindle size corresponding to the bar clearance and place them on a conveyor belt.

The universal turning machines are now also available with an integrated iXcenter robot cell to support fully-automated operation. It is located on a platform equipped with linear guides and is fixed in front of the machine's working area during production. The 6-axis robot offers up to 12 kg load capacity and accesses the machine's working area via the machine door, which opens automatically behind the robot cell. The iXcenter features a space-saving vertical storage system with up to 22 stacked pallets (600 mm x 400 mm). Downstream processes, such as cleaning, measuring and deburring, can also be integrated into the robot cell.

Features of the TRAUB TNA500:

- Rigid mineral cast bed in 45° block design for high accuracy

- A11 working spindle with belt drive for high torques

- Spindle clearance O102 mm, chuck up to O400 mm

- Generously designed bed guides

- Radial turret for 12 tools with VDI 40 mounting and W-serration for high process reliability, or disk-type turret for 12 tools with VDI 40 mounting

- Orthogonal, linear Y-axis for high accuracy

- Large axis traverse paths: 245 mm x ±60 mm x 750 mm (XYZ)

- iXpanel i4.0-ready operating system.

For more information contact:

INDEX Corporation

14700 North Pointe Blvd.

Noblesville, IN 46060

317-770-6300

sales@index-usa.com

us.index-traub.com

SOUTHWEST

NM

AME, Inc.

5770 Clarkson

Unit C

Denver, CO 80216

303-922-9266

www.amerm.com

AR, LA

Cardinal Machinery

7535 Appling Center Drive

Memphis, TN 38133

800-264-8511

www.cardinalmachinery.com

TX

Prosper Machine Tools, LLC

7415 Whitehall Street

Suite 123

Richland Hills, TX 76118

682-626-5537

www.prospermt.com

SOUTHEAST

AL, FL (Panhandle), MS, TN

Cardinal Machinery

7535 Appling Center Drive

Memphis, TN 38133

800-264-8511

www.cardinalmachinery.com

NORTHEAST

CT, ME, MA, NH, W. PA, RI, VT

INIRAM Precision Machine Tool Inc.

333 North Main Street

Middleton, MA 01949

978-854-3037

www.iniram.com

DE, MD, NJ, S. NY, E. PA

Single Source Technologies, Inc.

2192 Winterberry Court

Warrington, PA 18976

610-430-3670

www.singlesourcetech.com

MIDWEST

S. IL, KS, MO

Dynamic Machine Tool, Ltd.

84 Hubble Drive

Suite 200

St. Charles, MO 63304

636-447-2900

www.dynamicmachinetool.com

N. IL

Integrated Machinery Systems

101 North Prospect Avenue

Itasca, IL 60143

630-250-8305

www.imscnc.com

MI

Methods & Equipment Associates

31731 Glendale Avenue

Livonia, MI 48150

734-293-0660

www.methods-equipment.com

MI (Upper Peninsula), E. WI

Premier Machine Tool Midwest

PO Box 102

Hartland, WI 53029

414-254-5150

www.pmtmidwest.com

IN, KY, OH

Technical Equipment

10165 International Blvd.

Cincinnati, OH 45246

800-852-0582

www.techequip.com

WEST

CO, WY

AME, Inc.

5770 Clarkson, Unit C

Denver, CO 80216

303-922-9266

www.amerm.com

AZ

CNC PROS

1502 N 17th Ave.

Phoenix, AZ 85007

602-332-5815

www.cnc-pros.com

N. CA, NV (Reno & Carson City)

CNC Solutions

1011 Pecten Court

Suite A

Milpitas, CA 95035

408-586-8236

www.cncsolutions.biz

OR, WA

Ellis Machinery & Equipment, Inc.

6225 20th Street East

Fife, WA 98424

253-926-6868

www.ellismachinery.com

S. CA, NV (Clark County)

Protek CNC

25 W Easy Street

Suite 306

Simi Valley, CA 93065

805-579-9995

www.protekcnc.com