"For fabricators who want to expand the capabilities of their standard flat-plate cutting system, ESAB's SmartPipe package enables an affordable way to add pipe cutting and plasma marking capabilities," said a company spokesperson.

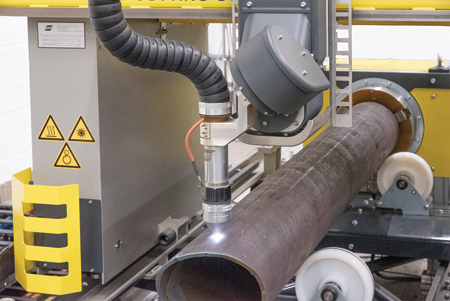

ESAB Welding & Cutting Products offers its SmartPipe system for automated plasma or oxy-fuel cutting of pipe alongside a table for cutting flat plate. The SmartPipe standard line covers pipe in diameters from 2" to 12", lengths up to 20' and weights up to 2,200 lbs. SmartPipe HD (heavy duty) can handle pipe diameters up to 10' (including the common 36", 48" and 72" diameters) and lengths up to 60'.

The SmartPipe system consists of a pipe turning unit with a manually adjustable chuck and a CNC-controlled turning axis, two or more adjustable-position pipe supports and a support track. A typical configuration would situate the turning unit between the cutting table and gantry rail (oriented parallel to the rail), but it can be located behind the table as well (e.g., parallel to the gantry).

SmartPipe also includes graphical programming software that creates programs for straight or bevel cuts for any pipe application, such as saddles, holes, slots or weld cut preparations. The software, which runs on ESAB's Vision controller, generates a 3D rendering of the finished pipe so users can confirm details before cutting.

"The SmartPipe package provides an affordable pipe cutting addition to standard flat-plate cutting machines," said Steve Zlotnicki, Global Product Manager, ESAB Cutting Systems. "SmartPipe opens new opportunities for shops that want the flexibility to cut or bevel pipe but cannot justify investing in a stand-alone cutting system." As examples, he cites shops that want to target processing industries, pressure vessels and infrastructure projects that incorporate tubing into their designs.

For straight cuts, pair SmartPipe with any standard oxy-fuel torch or plasma system for cutting at up to 200 amps. For cutting bevels, pair SmartPipe with a bevel head such as ESAB's DMX Plasma Beveller or VBA (variable bevel angle) wrist.

For more information contact:

ESAB Welding & Cutting Products

411 S Ebenezer Rd

Florence, SC 29501

800-ESAB-123

www.esabna.com