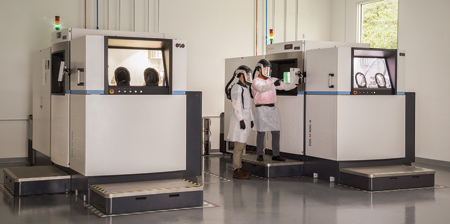

Two of Sintavia's EOS M400 printers at its Hollywood, FL, advanced manufacturing facility.

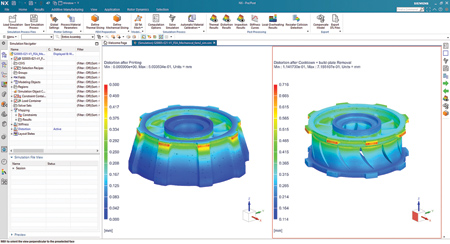

Simulation designed by Sintavia of an aerospace nozzle guide vane ring, both with and without supports, using Siemens Xcelerator simulation.

Sintavia, LLC, a Tier 1 additive manufacturer supporting the aerospace, defense and space industry, has acquired two additional M400-4 quad laser printers from EOS GmbH. The printers represent the seventh and eighth M400 printers operated by the company, as well as the 20th and 21st industrial printers it owns overall. The purchases follow Sintavia's announcement in July of its acquisition of an additional Arcam Q20+ electron beam printer from GE Additive.

"As we have grown over the past several years, we have shied away from issuing press releases when we acquire new equipment. In a normal year, these announcements are kind of boring. However, this is an unusual year, and we feel it is important to let the industry know that demand for aerospace additive manufacturing (AM) is booming," said Brian Neff, Sintavia's CEO. "The global pandemic has turned the traditional aerospace supply chain on its head, creating real opportunities for companies like Sintavia to offer high precision solutions to OEMs worldwide, and this trend underpins this announcement. The EOS M400-4 is the workhorse of our factory, and we continue to see great results with it."

The company stated that it expects to add an additional six to eight large industrial printers by the end of 2021, and eight to 10 more in 2022.

Accelerating Digital Automation for Industrial AM

Sintavia has entered into an agreement to collaborate with Siemens Digital Industries Software on the development of an end-to-end AM software solution as a part of Siemens' Xcelerator portfolio. Sintavia will provide testing and technical feedback on pre-released software that will be part of future AM solutions. In exchange, Sintavia becomes a preferred AM partner of Siemens and gains access to the software in advance of the market, along with technical support for its implementation.

"We are excited to be collaborating with Siemens to help make industrialized AM a reality," said Neff. "The end-to-end solution that Siemens has been developing is absolutely essential to making additive a viable manufacturing process."

Neff noted that the value of the Siemens AM solution goes beyond digitally connecting the various phases of the AM process. "We have developed a lot of tribal knowledge on how to deliver quality 3D printed metal parts," he explained. "But we recognize that we cannot just rely on individual expertise to meet the accelerating demand in aerospace for AM. We need software to codify the processes we undertake, and not just connect them in a digital thread, but automate them, take our know-how and have it drive activities in the background so we can achieve optimal efficiency."

Aaron Frankel, Vice President of the AM Program for Siemens Digital Industries Software, added, "The collaboration with Sintavia is vital to our efforts to develop an automated end-to-end solution that spans the entire AM lifecycle-from designing an optimized part, preparing it 3D printing and simulating its build, to planning serial production, executing on the shop floor and delivering a qualified part."

"With their depth of experience and track record in the market," Frankel continued, "Sintavia can provide the kind of technical feedback we need to build AM know-how into our digital twin and make the system the expert as opposed to the user. This is a critical step to making additive more widely embraced for volume production. Unlike traditional manufacturing, additive is a process where we do not have decades of established knowledge that is readily communicated, whether in software or through technical education. Companies cannot afford to make everyone in the AM process an expert; they need the software to automate some tasks, work in the background and make additive more of a push-button process."

As part of the three-year agreement, the two companies will collaborate on joint sales and marketing activities and plan to organize events at Sintavia's facility that will showcase Siemens' AM solution in an industrialized additive production environment.

The companies have agreed that sustainability will be a focus area for their marketing collaboration. In November 2019, Sintavia co-founded the Additive Manufacturer Green Trade Association (AMGTA), a global, non-commercial, unaffiliated nonprofit organization open to any additive manufacturer or industry stakeholder that meets certain criteria relating to sustainability of production, and Siemens joined AMGTA in 2020.

"Siemens has a strong commitment to sustainability-it is a key part of the Siemens 2020+ vision," said Frankel. "Siemens' AM software contributes to greener AM production not just by streamlining designs and reducing material usage, but also by leveraging simulation to help enable first-time-right 3D printing and optimize AM factory efficiency to eliminate waste. We are excited to join the AMGTA and work closely with Sintavia to help promote the green benefits of AM."

For more information contact:

Sintavia, LLC

2500 SW 39th St.

Hollywood, FL 33312

954-474-7800

info@sintavia.com

www.sintavia.com