Robotic Load/Unload System with Secondary Operations Capability

December 1, 2020

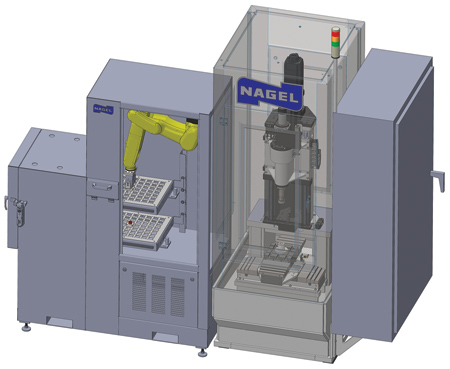

RL-2000 integrated robotic machine loading system with secondary operations capability

Nagel Precision, Inc. has developed a new robotic load unload system that is capable of performing secondary operations, permitting manufacturers to achieve lights-out manufacturing. "With ethernet and profinet communications inside the FANUC controller, the need for expensive standalone controls is eliminated because the controller inside the machine is utilized," said a company spokesperson. This system can be integrated into both old and new CNC and PLC based machines.

"Traditionally available automatic machine tending/pallet systems are solely dedicated to loading and unloading. In many instances, parts are later deburred, stamped, gauged, etc. In addition to performing the machine tending, this new Nagel RL-2000 loader can also accomplish these secondary operations," said the spokesperson.

Nagel RL-2000 Integrated with Nagel ECO 20 Honing Machine

The loader can be configured for either front or side loading applications. The operator opens the interlocked safety door and manually unloads up to four finished trays and loads green trays. Trays are mounted on heavy-duty rails that can be pulled out like drawers, and once the tray is complete the robot will push it back in and pull the next tray out. Sensors ensure that trays are in place to prevent any crash. The robot can drop a finished part from time to time into a SPC Shute for offline inspection. The robot can be equipped with automatic gripper changers for rapid changeover.

The system is of heavy-duty construction and meets stringent automotive OEM specifications. The loading system can be customized to suit individual requirements and is delivered turn-key.

For more information contact:

Nagel Precision, Inc.

288 Dino Drive

Ann Arbor, MI 48103

734-426-5650

info@nagelusa.com

www.nagelusa.com

< back