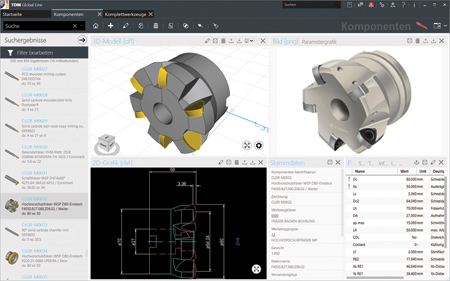

TDM Global Line provides an overview of the entire tool: 2D, 3D and parameter graphics with master data.

With the new release of TDM Global Line 2019, TDM Systems offers many of the functions of its core solution. The TDM core solution is comprised of TDM Shopfloor Manager, TDM Production Document Management, Graphic Functions and TDM WebCatalog.

"The global use of a central database results in massive IT cost savings, productivity increases and synergies that span multiple locations," explained Eugen Bollinger, Vice President Sales at TDM Systems GmbH. "In order to increase the added value for the user even further, we have expanded the configuration options in TDM Global Line 2019 and developed new modules."

TDM Shopfloor Manager is a powerful tool designed to allow for comprehensive workflow management, incorporating booking functions and many interfaces for crib systems, presetting devices and machines as well as for higher-level systems such as MES, FMS and ERP. Users can now create multiple shop floor configurations in order to depict workflows in various production areas. A new feature is individual status management, which allows an individual to define the tool status themselves within the workflow.

TDM Production Document Management is a new module that allows users to assign as many documents as they wish to the production resources via a drag-and-drop function - either in the form of a link to the actual saved location or as a copy on the TDM Global Line server.

New Graphics functions allow the user to generate rotation contours from 2D graphics using the Tool Contour Generator, with just a few mouse clicks and the aid of an intuitive user navigation system. In combination with the TDM 3D-Rotation Generator, simulation-ready 3D models for realistic collision checking in CAM systems can be generated within of a few seconds.

With the release of TDM Global Line 2019, upon registering with TDM systems, users will have access, through the TDM WebCatalog, to the latest tool catalogs in the cloud and can therefore obtain consistently up to date, verified tool data from leading manufacturers.

"Users of TDM Global Line 2019 will also be able to discover plenty of other innovative features alongside those already mentioned, such as the individually customizable user interface," said a company spokesperson. "With TDM 2019, the future is hybrid. TDM has invested a great deal of expertise and resources into the further development of the TDM core solution. Users of TDM 2019 can benefit from the new hybrid mode: They can use Global Line modules such as the Shopfloor Manager in combination with the TDM 2019 version." Access to the TDM WebCatalog is also possible for the current version. Everyday work can also be facilitated via the expanded Multiple Plant Management system, which allows equipment to be assigned with even greater precision.

For more information contact:

TDM Systems

1901 N. Roselle Rd., Ste. 800

Schaumburg, IL 60195

847-605-1269

info@tdmsystems.com

www.tdmsystems.com