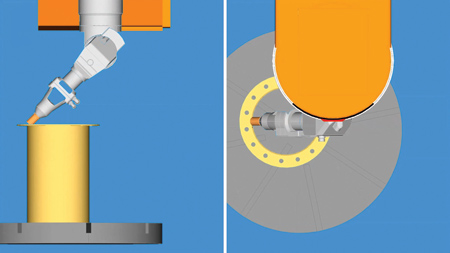

SmartComp from Prima Power Laserdyne is an easy-to-use tool to address misalignments of parts and fixtures on an integrated rotary table axis. It corrects the programmed position and angle of the laser beam in real-time based on the real part location and orientation.

SmartComp is the latest SmartTechnique from Prima Power Laserdyne. SmartComp is an application inspired programming tool designed to ensure that laser welds, laser drilled holes and laser cut features on 3D parts processed using a rotary table are in the most precise location.

SmartComp is an easy-to-use tool to address part variation and misalignments due to part placement on a rotary table or on a fixture attached to a rotary table. Prima Power Laserdyne's SmartComp corrects the programmed position and angle of the laser beam in real-time when: (1) the center of the part is not aligned with the center of the rotary table or (2) the part is tilted from the center of rotation of a rotary table.

SmartComp can be used to compensate for both linear offsets and axis precession on parts processed on a rotary table, even if the parts are flat, round, conical or contain curved surfaces.

SmartComp makes it easy to calculate and implement the corrections by measuring the actual location of a small number of reference points on the part and comparing the actual position of these points within the laser processing program. During processing, SmartComp automatically adjusts the coordinate system in real time so that the programmed positions line up with the actual part position.

SmartComp is ideal for laser welding because it compensates for real-world variations enabling the laser head to follow the intended weld path on the part accurately. With real time corrections from SmartComp, welds are more consistent requiring no operator intervention. The SmartComp feature is equally effective in drilling cooling holes in aerospace engine components.

SmartComp increases machine productivity by reducing the time to set up fixtures for new parts. Results ensure that laser welded, cut and drilled components are correctly processed the first time and with consistent repeatability.

The new SmartComp technique controls machine motion and does not affect operation of the laser itself. SmartComp, along with the complete suite of LASERDYNE SmartTechniques, is available on the LASERDYNE 795, 606D and 430 multi-axis laser systems. It is also available as a free software upgrade to current users of LASERDYNE systems with S94P software.

The SmartTechnique suite also includes SmartPerf, SmartPierce, SmartRamp, SmartSense, SmartShield and SmartStop. "With Prima Power Laserdyne's advanced, integrated control of all laser, motion and process sensors along with these unique processing techniques, users will achieve ground breaking results," said a company spokesperson.

SmartComp is one of the innovations of LASERDYNE'S S94P controller used in its 795, 606D and 430 multi-axis laser systems.

"SmartComp, along with the other SmartTechniques, lead to laser processes with greater capability, higher throughput, higher quality and greater flexibility," said a company spokesperson.

For more information contact:

Prima Power Laserdyne

8600 109th Ave. North, #400

Champlin, MN 55316

763-433-3700

lds.sales@primapower.com

www.primapowerlaserdyne.com