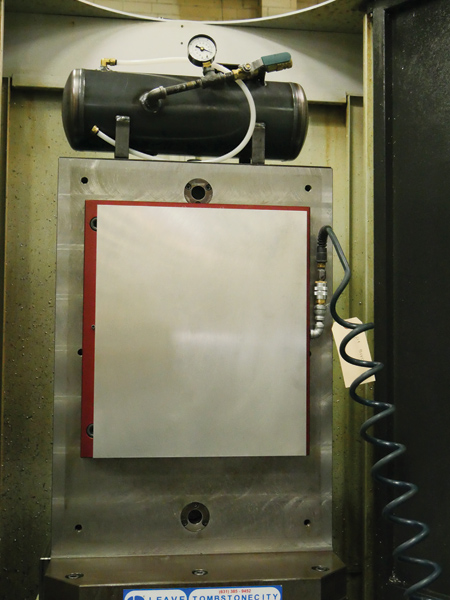

Lights-out Machine-Ready Blank shown on TCI Precision Metals vacuum chuck tombstone workholding solution.

Machine-Ready Blank, with added features requiring a large amount of material removal, reduces wear and tear on customer's machining centers and tools.

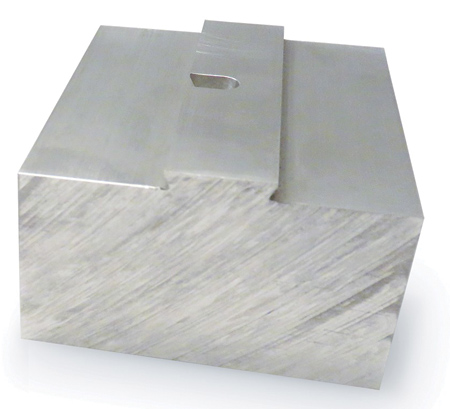

Dovetail Machine-Ready Blank for use in lights-on or lights-out 4- and 5-axis machining.

TCI Precision Metals has announced a line of Machine-Ready Blanks designed to eliminate material preparation, and support automated loading and unloading of machining centers engaged in lights-out or semi-lights-out operations.

Machine-Ready Blanks for lights-out operations pull from TCI Precision Metals' experience in producing close tolerance, pre-machined blanks, but include engineering and added features to ensure consistent material handling and workholding associated with lights-out operations. "TCI material specialists work closely with customers to design the most efficient Machine-Ready Blanks for each unique production job, with the goal of delivering Machine-Ready material that arrives to the customer ready to go from receiving directly into its CNC machining center," said a company spokesperson. "At TCI Precision Metals we add value to every part we ship, whether we supply the material or use customer supplied stock," said Ben Belzer, President of TCI Precision Metals. "Our experience producing precision, pre-machined material has allowed us to effectively support lights-out machining operations."

Machine-Ready Blanks for lights-out operation eliminate the need for in-house sawing, grinding, flattening, squaring operations and outside processing. Each blank arrives deburred, clean and to customer specifications - providing as close as +/- .0005" dimensionally and as close as .0002" flatness, squareness and parallelism. Given the use of automated loading and unloading machines, specialized fixturing and finished part geometry, there are often features or additional processing added to blank material before it is ready for finish machining.

Features and benefits include:

- Lights-out pre-machined features - By adding features to Machine-Ready Blanks, such as boring, drilling, hog outs or other features that require large amounts of material removal, excessive tool wear can be eliminated, parts can be lightened and overall wear and tear on the machining center reduced. Being able to assign features to a pre-machined blank can often determine the feasibility of a lights-out operation.

- Lights-out 4- and 5-axis machining - Machine-Ready Dovetail Blanks provide similar productivity benefits to customers using 4- and 5-axis machining centers fitted with a dovetail workholding fixture. Each Dovetail Blank includes a precision machined dovetail to match the brand and model of workholding fixture specified by the customer.

- Lights-out workholding - TCI Precision Metals specializes in making flat, close tolerance, Machine-Ready Blanks and has enhanced the Vacuum Workholding Solutions required to hold them as well. Vacuum workholding supports lights-out machining by securely holding plate material without the use of mechanical clamps, which simplifies automated loading and unloading.

For more information contact:

TCI Precision Metals

240 E. Rosecrans Ave.

Gardena, CA 90248

800-234-5613 / 310-323-5613

sales@tciprecision.com

www.tciprecision.com