According to Chauvin, the Techni i612-G2's biggest draw is its cutting speed. "In the time trials that we have done, it is cutting faster than a larger waterjet would," he said. "In fact, the G2 was able to complete some jobs up to 40% faster than Hydro-Blade's previous waterjets."

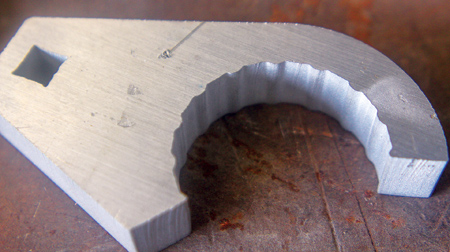

A variety of workpieces cut on the Techni i612-G2.

When Hydro-Blade Waterjets merged with Paragon Metalworks in August 2018, owners Ben Chauvin and Charles Green needed to invest in new machinery to expand their business.

Keeping the Hydro-Blade name, Chauvin knew that one of the shop's first purchases was going to be a new waterjet. "As time has gone on, I have seen the changes in the market and how the technology has improved," he said. "I think it is foolish if you do not look to see what else is out there."

Seeing what else is out there led Hydro-Blade to Techni Waterjet. Chauvin was initially attracted to the waterjets' ease of maintenance, usability and low cost of consumables. After visiting machine shops using Techni waterjets and consulting with Kearney Machinery, Techni's local dealer, Chauvin decided Techni's i612-G2 (formerly called TJ4000-X3) was the best fit for Hydro-Blade and purchased the waterjet from Kearney Machinery.

According to Chauvin, the i612-G2 series' biggest draw was its cutting speed. "In the time trials that we have done, it is cutting faster than a larger waterjet would," he said. "In fact, the G2 was able to complete some jobs up to 40% faster than Hydro-Blade's previous waterjets." Techni's Electric Servo Pump (ESP) gets most of the credit for this increase in productivity. The ESP is unique in the marketplace; the designed-in efficiencies allow for the faster cutting, easier maintenance and more runtime between maintenance cycles.

Techni's Tech-Sense technology monitors the cutting head and pauses the job before any blockage. Tech-Sense, along with the ability to monitor the job from any smart device, has allowed Hydro-Blade to run the machine lights-out without worrying about wasting costs by way of scrap or consumables. Chauvin described Techni's advanced diagnostics and troubleshooting system as "a mix of the man running the machine, and the machine running the man," adding that "it can save me 30 minutes to two hours trying to diagnose the problem, and that equates to saving money."

Besides the machine itself, Chauvin knows that service is just as important. "I do not care what type of machinery you have," he said. "If you do not have the service to back it up, I do not even want to have a conversation."

With the i612-G2, Hydro-Blade has already seen workflow improvements-especially when it comes to ease of use. "I took one of my guys who was a plasma operator with very little experience on waterjets. We put the Techni on the floor, brought him in, and had him go through the learning process. He has stepped up to be my lead operator. When you can have somebody who is sweeping the floor, and in three or four hours have them running the machine, it is a pretty significant move," said Chauvin

Hydro-Blade expects to continue expanding its shop, broadening its footprint and increasing its workforce. Hydro-Blade also plans on becoming more of a product-based company manufacturing other companies' products and even designing its own. So far, the Techni i612-G2 is making Hydro-Blades growth possible, and the shop plans on purchasing additional Techni waterjets. "I can tell you what is needed and not needed for our applications. Techni fit the bill and the price point was there. It made sense," said Chauvin.

Hydro-Blade Waterjets is a machine shop in Broussard, LA, that specializes in waterjet cutting, plasma cutting, fabrication and machining.

For more information contact:

Hydro-Blade Waterjets

336 Industrial Parkway

Lafayette, LA 70508

337-257-3154

www.hydrobladewaterjets.com

TECHNI Waterjet

888-TECHNI-3 / 913-492-3700

sales@techniwaterjet.com

www.techniwaterjet.com

Kearney Machinery

124 Citation Court

Birmingham AL 35209

205-942-1100

www.kearneymachinery.com