5-axis swarf machining has been made more flexible in FeatureCAM 2016

Delcam has launched the 2016 release of its FeatureCAM feature-based CAM software. This includes a range of enhancements, in particular more options for the Vortex high-efficiency area-clearance strategy, support for bar-fed mills, more efficient turning and user interface improvements to make programming easier and faster.

"FeatureCAM was the world's first feature-based programming software when it was launched in 1995. Constant development since then has ensured that the system has retained its programming speed and ease of use, while an increased range of strategies has been added to provide more efficient toolpaths that give greater productivity on a wider range of machinery, including mill-turn machines, 5-axis mills and wire EDM equipment" said a company spokesperson.

The 2016 release includes a number of enhancements to the Vortex area-clearance strategy. Vortex is designed to provide fast, safe metal removal from solid carbide tooling, in particular designs that give deeper cuts by using the full flute length as the cutting surface. "It produces toolpaths with a controlled engagement angle and so maintains the optimum cutting conditions for the complete roughing cycle," said the spokesperson.

The ability has now been added to adjust and fine tune the non-cutting moves of 2.5-D and 3-D Vortex toolpaths, with options to retract the tool and/or to increase the feedrate. These options can be set individually, or can be combined for an optimum toolpath with a reduced cycle time.

"Other roughing improvements include the ability to take into account any remaining stock on the model during holder collision checking, ensuring that Z-level roughing toolpaths are completely free of toolholder collisions," said the spokesperson.

Milling of inside or outside groove features has been upgraded with a number of improvements. These include support for different types of roughing links, wind-fan approach and retract moves for finishing, better gouge checking for plunges and retracts, and tool radius and partline cutter compensation support.

Support has been added to FeatureCAM for multitasking bar-fed milling machines, such as the Mazak Integrex I150, and the Willemen-Macodel 408T and 508T. Access to the back of the component is possible with an option to set the swivel angle of the machine, with additional cut-off operations now available that use milling tools.

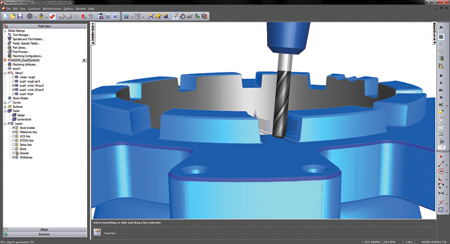

Five-axis swarf machining has been made more flexible with an option to control the upper and lower Z limits of a simultaneous 5-axis swarf toolpath. "This is useful if there are limitations on the tool length that can be used or if the stepdown needs to be varied for different segments of the toolpath," said the spokesperson.

For users of FeatureTURN, the selection of turning tools has been simplified with the ability to use a single tool in multiple orientations. This automatic tool orientation categorizes tooling into either outside diameter or inside diameter turning tools, so shortening the time taken to program parts and reducing the number of different tools required in the tool crib.

In addition, the engage angle can now be set for the lead-in approach move. "By controlling the approach move in this way, smoother chip formation and lower cutting forces can be achieved," said the spokesperson.

FeatureCAM now allows the quick import and alignment of a variety of pre-defined vises and chucks into a machining project. "The result is increased productivity, not only due to the speed of programming but also because collision checking is provided automatically during simulation," said the spokesperson.

Used in combination with PowerSHAPE, FeatureCAM now allows machining files to be selected and nested automatically in a single block to optimize stock material usage.

Interface improvements include the ability to create additional set-ups quickly during FeatureRECOGNITION, via a new button in the Feature Wizard. This is designed to reduce the overall programming time.

In addition, items within the part view are now highlighted when the cursor hovers over them. At the same time, the items are also highlighted in the graphics screen to make it easier to find and select the desired items quickly.

Finally, Autodesk RealDWG has now been integrated into FeatureCAM, bringing with it increases in the speed of import of DWG files and support for DWG solid model import.

For more information contact:

Delcam

877-335-2261

marketing@delcam.com

www.delcam.com