In the Americas, customers can receive fast and efficient support for the Schuler Laser Blanking Lines.

The German press manufacturer Schuler has numerous manufacturing and service locations worldwide so that customers can receive fast and efficient support from local Schuler employees. In the Americas, for example, there are sites in the USA, Mexico and Brazil, ready to support one of the company's latest innovations: the Laser Blanking Line.

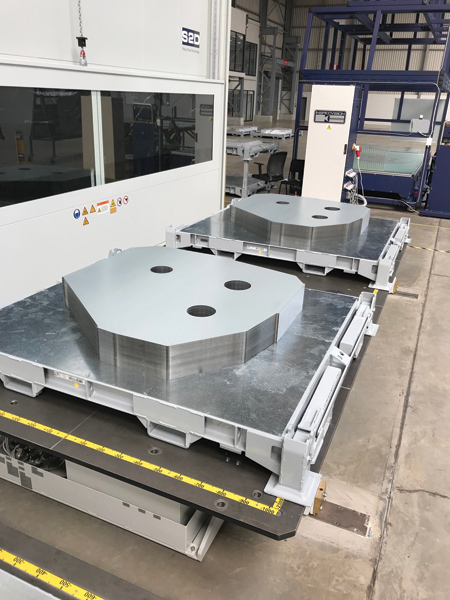

Laser blanking makes it possible to manufacture blanks completely without dies. Instead of using presses or shears, the geometries are cut by two or three high-precision laser heads. "This has several advantages, including no dies, die change, die storage or die maintenance, and also no costly press foundation and no loop pit," said a company spokesperson. "The technological development of laser performance, combined with intelligent line automation, enables Schuler to achieve cutting speeds of up to 100 meters per minute (328 ft/min)."

The design of a Laser Blanking Line is similar to a conventional press cutting line. "Simply said, the press is only replaced by a laser cell," explained Oswald Schoenberger, Product Manager for Laser Blanking Lines. "Operators who already have experience with conventional blanking lines can learn to handle the system very quickly. After completing our training program, operators without blanking experience find it easy to handle as well."

"Programming the lasers also requires no process expertise due to LBL Studio," said the spokesperson. "The offline program is so intelligent that cutting contours for new parts are automatically created based on CAD files. The optimal cutting distribution of the lasers is taken into account and reliable predictions about the output can be calculated in advance. Changes can be made manually at any time."

"With our team of 80 qualified service employees we are ready to provide high quality technical support to all our customers in North America," said Telvi Zanin, Vice President of Service. "Our trained employees can thus react quickly and provide optimal on-site service. In addition, remote services like Schuler Connect offer the possibility of immediate assistance from our headquarters in Canton, MI, or from our experts in Germany if required, for established products as well as for innovations such as the Laser Blanking Line."

For more information contact:

Schuler Inc.

7145 Commerce Blvd.

Canton, MI 48187

734-207-7200

info@schulerinc.com

www.schulergroup.com