High Efficiency Tube Bending

August 1, 2021

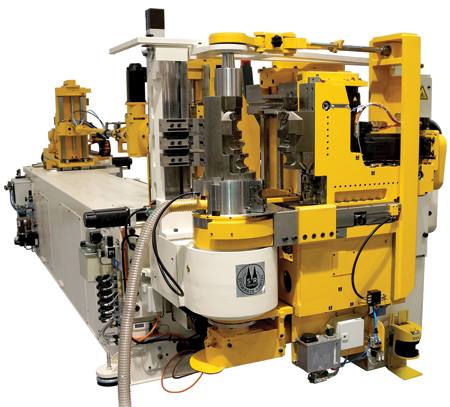

The fully equipped, fully electric CNC 80 E TB MR multi-radius tube bending machine is especially suited to the requirements of the automotive industry.

Schwarze-Robitec will present its fully equipped, fully electric CNC 80 E TB MR multi-radius tube bending machine.

Designed for high volumes, short cycle times and resource-saving material handling, the CNC 80 E TB MR is especially suited to the requirements of the automotive industry. "Production time is reduced by up to 40% compared to conventional machines, depending on the component and the desired tube geometry," said a company spokesperson. "Material waste is reduced by 90%. The contact pressure can always be optimally gauged, while tool costs and changing times are reduced. Overall, the use of the CNC 80 E TB MR increases repeatability and process reliability."

Schwarze-Robitec's high-performance series bends and cuts tubes in a single work step due to an integrated fully electric cutting device. An extended vertical transport carriage makes this possible despite the multi-stack bending tool. A vertically adjustable pressure die moves to the different levels for bending synchronously with the tube.

The intelligent NxG control checks the interaction of all machine axes for each bending sequence and simultaneously prepares all axes for subsequent steps. In addition, the CNC 80 E TB MR is equipped with the Quick-Tool-Unlock tool changing system in combination with a rapid clamping system for the bend former. This makes it easy to open and close the tension bars for tool changing, while no bolts are required to fasten the bend former to the turntable.

For more information contact:

Schwarze-Robitec America Inc.

3566 Roger B. Chaffee Memorial Blvd.

Wyoming, MI 49548

616-278-3971

us-sales@schwarze-robitec.com

www.schwarze-robitec.com

FABTECH Booth D45954

< back