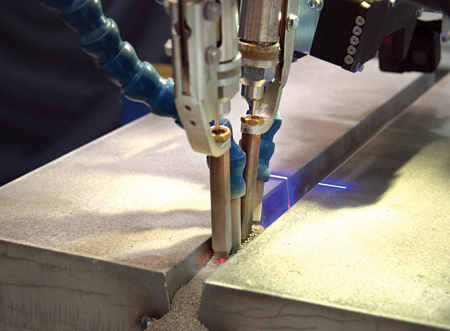

PEMA WeldControl 500 laser scanning software for weld seams "reads" the weld groove before the weld and after the weld from two separate angles, improving weld accuracy and precision.

Pemamek LLC, North American subsidiary of Finland-based Pemamek Ltd., will exhibit its welding automation technology at FABTECH 2021. Two highlights will include laser scanning software for weldments and its dedicated expertise and technology for the offshore wind manufacturing sector.

Named PEMA WeldControl 500, the new laser scanning software for weld seams "reads" the weld groove before the weld and after the weld from two separate angles. In this new laser scanning solution, essentially the operator of the automatic welding system sees a graphical representation of the weld groove geometry on a display screen at any given point in the seam. It can be conveyed in several different ways, such as a groove fill graph. It presents and saves every piece of data, including speeds, fill volumes, temperatures, amperages and more. The scanning process acquires and stores the geometric, speed and fill data as the robot welder travels along the seam. Alarms are set to sound or message when the weld goes out of tolerance of whatever parameter ranges are established in advance in the system. The welding operator can then go back and resolve the issue and let the customer know that a repair was made at exactly where, when and the weld application parameters.

Another benefit with this new technology is having remote access to the welding data out in a wind farm or at the power plant or wherever the installation stands or floats. For example, the data can be stored securely in the cloud while the wind tower or ship hull in question has a QR code associated with it that can be scanned by a QR code reader on a smartphone and the specific data can be reviewed.

"Nowadays, it is all about data," said Michael Bell, Director of Sales-North America. "This technology not only provides data for each point along the groove, but it is accurate, reliable and searchable data that is extremely helpful to our customers and their customers, all the way down through the supply chain."

Pemamek offers several packaged solutions for the welding of wind tower production. For example, there will be displays of its WS Welding Platform, the HFF Horizontal Flange Fitting Station and Robotic Node welding technology. Wind sector experts will be available to share best practices in automatic welding for wind towers and foundational structures.

For more information contact:

Pemamek LLC

20333 State Highway 249, Suite 200

Houston, TX 77070

513-206-0807

info.us@pemamek.com

www.pemamek.com

FABTECH Booth B35038