Trevor McCoy, CNC/EDM programmer at Clippard, runs a FANUC wire EDM with the GIP proprietary PLASMA coated brass wire. McCoy stated he achieves better finish with 15% to 20% improvement in run time.

Clippard uses wire EDM for the production of many components, including the tooling used in its conventional machine shops. All EDM work at Clippard is performed for internal production purposes, so one-offs are common, making speed a critical factor for the department.

Proprietary hybrid PLASMA coated brass wire from GIP

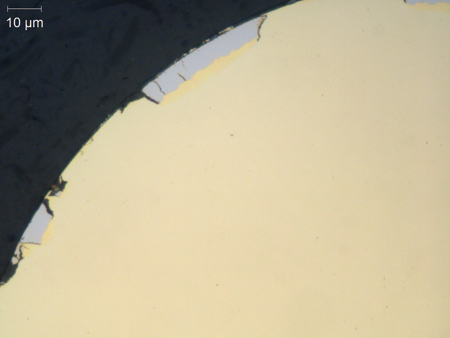

Cross section and surface views of the PLASMA coated brass EDM wire shows the discontinuous layering, caused by fracturing during the diffusion annealing process. This surface formation actually enhances the flushing of the workpiece during machining.

The Clippard "Air Guitar" produced by the engineers and manufacturing specialists at Clippard, using the company's pneumatic components.

Clippard, a provider of fluid control products and other high-precision components, operates two ISO certified manufacturing locations in Ohio and does advanced machining of all types to produce its catalog of standard and custom product solutions for a myriad of markets worldwide. At the heart of its machining capabilities are 12-axis CNC Swiss machines, CNC milling centers and CNC wire EDMs, plus numerous post-finishing operations, including anodizing, EN plating and thermal deburring. Various metal and thermoplastic materials are machined.

Recently, after extensive discussions with a local EDM supply distributor, a proprietary hybrid coated brass wire was presented to the Clippard Director of Operations, Robin Rutschilling and his CNC/EDM Programmer, Trevor McCoy by Barry Ramsay of Global Innovative Products (hereafter GIP), a Mason, OH, supplier of consumables for EDM shops through their GIP distributor network, who also produces a variety of its own products for need-specific operations in electrical discharge machining. One such product is a PLASMA hybrid coated brass wire, comprising of a gamma-phase intermetallic zinc alloy coated wire with brass core. This proprietary GIP innovation had proven out in numerous lab testings but needed "real world" production validation. Barry Ramsay and GIP Application Engineer Brad Hansard approached the team at Clippard.

As the product had been found suitable for all types of wire machines, with excellent auto-threading capability and increased performance, even at conventional brass wire settings, Ramsay felt confident the product would outperform what Clippard was currently using in its EDM shop, including other GIP wire. This new product was being offered in 0.008", 0.010" and 0.012" (20 mm, 25 mm and 30 mm) diameters, so Ramsay proposed giving the Clippard EDM department a supply for testing on one of its FANUC wire machines.

Gamma phase brass is a brittle intermetallic alloy (Cu5Zn8) with a high zinc content (approximately 65% Zn) which can also be synthesized by a diffusion anneal. However, when such coatings are wire drawn subsequent to the diffusion anneal, the coating will fracture due to its brittleness and redistribute around the wire circumference creating a discontinuous layer sometimes described as a "porous layer", which promotes turbulent flow enhancing the flushing of debris. However, it is zinc enrichment created at the surface combined with the elevated melting point of CuZn gamma phase (approximately 800 ºC/1,472 ºF) which are the biggest factors contributing to the performance of Gamma Phase Brass coated wire.

The arrangement between the two companies actually began in a somewhat unconventional manner, as Trevor McCoy related. "We have an Ocean hole popper (electrode/sinker EDM) and the circuit boards needed repair. Brad was able to do that kind of work, which I knew from previous experiences with him. So, he proposed exchanging the board servicing for the opportunity to test the GIP hybrid PLASMA wire. Seemed reasonable to us, so we agreed." The FANUC wire EDM in the shop at Clippard seemed an ideal candidate for GIP, as well, as Barry Ramsay noted, "We knew they were running all types of materials and some high-precision tooling used in their own machine shop for the production of various pneumatic components with tight tolerances. It seemed a good place to test our new wire, which had been proven out on our own EDMs at GIP." He further said it was a handshake deal, a "classic collaboration between two companies for their mutual benefit," adding that application engineering supplied by GIP further enhanced the use of the product at Clippard, as the test learning process information was shared without reservation, so both companies benefited.

In this test case, many of the components were being run for the production of special parts being produced by Clippard for robotic arm articulation.

The testing immediately yielded positive results, as McCoy noted they were holding tolerances under a tenth, with a microfinish that was important for the application. "We do a lot of custom work for our own use, over 50% of my production in EDM. Some of the hard tool steels are difficult to drill and we also run various others. The jobs require a lot of set-up time and fixturing, so run time, finish and wire breaks all are critical for us."

The goals for this proprietary wire testing were three, according to Barry Ramsay. "The characteristics of the PLASMA wire in production on the FANUC machine at Clippard were important, as the flushing of their precision components directly impacts quality. Further, we had our own test results galore but needed an outside house to validate what we were seeing. Lastly, we just wanted to help our friends at Clippard, who had been so cooperative and, in this case, needed our help with those circuit boards. It was a classic win-win for both of us, as all three goals were met."

Multiple parts were EDM'd during the testing of this PLASMA wire, with full comparative data tracked on the test wire vs. conventional brass. One tool for a medical part was produced, for example, in :56 vs. 1:05 with five skim passes, a 16% improvement in overall production. McCoy noted, "We could apply more power to run faster. The GIP product consistently outperforms premium brass, based on my experience with both now. The PLASMA wire is as clean as conventional brass. The price point is also competitive, so there is less of a premium to achieve these enhanced results."

Clippard is a third-generation, family-owned and operated company that has developed many pneumatic components for a variety of applications in industry, commercial and even fun applications. Clippard's Chief Marketing Officer, Rob Clippard, developed this "air guitar" that operates with the company's pneumatic valves and cylinders.

Authored by Chris Agricola, Advertising Manager, Clippard

For more information contact:

Robin Rutschilling

Director of Operations

Clippard

7390 Colerain Avenue

Cincinnati, OH 45239

513-521-4261

r.rutschilling@clippard.com

www.clippard.com

Barry Ramsay, General Manager

Global Innovative Products

7697 Innovation Way

Suite 200

Mason, OH 45050

513-701-0441

bramsay@gipintl.com

www.gipintl.com