EGM-80CNC universal ID/OD grinder

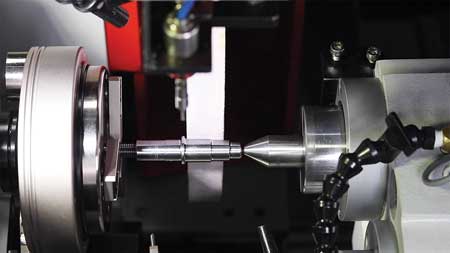

Mini Genie CNC cylindrical grinder

At the Manufacturing Technology Series WEST 2025 booth 1230, Supertec will highlight two of its most space-efficient, high-performance grinding machines: the Mini Genie CNC cylindrical grinder and the EGM-80CNC universal ID/OD grinder. These machines are built to meet the needs of modern manufacturers seeking compact, flexible and automation-ready solutions for precision grinding.

Mini Genie 2520CNC

With a footprint under 32.3 sq. ft., the Mini Genie is designed for shops where space is at a premium. Equipped with Mitsubishi M80 conversational control, it offers OD, end face and form grinding capabilities. It is available in plunge and angle head models.

Features include a 20" x 2" x 6" grinding wheel driven by a 7.5 HP spindle motor. A 0.000002" HEIDENHAIN linear scale is used for precise positioning of the wheelhead while a taper adjustable tailstock removes any possible tapers in the workpiece. A Mitsubishi M80 control with Supertec's conversational i-Grind software allows for entry level programmers while offering advanced programming operations needed to grind complex parts.

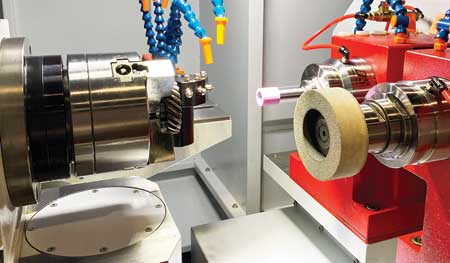

EGM-80CNC

Designed for small, complex parts, this machine offers enhanced chucking precision ID/OD geometries, including face and conical surfaces. It features powerful grinding performance in a compact form, making it well-suited for shops with limited floor space. With a workpiece envelope of 3.15" depth x 9.4" swing and 55 lb. weight capacity, the EGM-80CNC is versatile. Features include a range of spindle RPMs from 8,000 to 50,000 allowing for a wide range of grinding capabilities. With precision linear ways and ballscrews on all 3 axes, the grinders movements are fast and accurate, helping to reduce cycle times. A Mitsubishi M80 control with Supertec's conversational i-Grind software is standard.

Savings in cycle times as well as increased production can be achieved on the MINIE GENIE and EGM-80CNC with the integration of optional touch probes and automatic sizing devices as well as gantry style or articulating arm robotics.

Attendees are invited to see live demos and speak with the Supertec Team about customized grinding solutions for a wide range of industries, including aerospace, automotive, defense, medical and general manufacturing.

For more information contact:

Supertec Machinery Inc.

6435 Alondra Blvd.

Paramount, CA 90723

562-220-1675

info@supertecusa.com

www.supertecusa.com

MT Series WEST Booth 1230